Wood Pellet Making Machine Ring Die Pellet Mill For Sale

| Model | YGKJ700 |

| Capacity | 2-2.5T/H |

| Power | 160+2.2+ 0.37+0.75 +1.5KW |

You can now ask our project managers for technical details

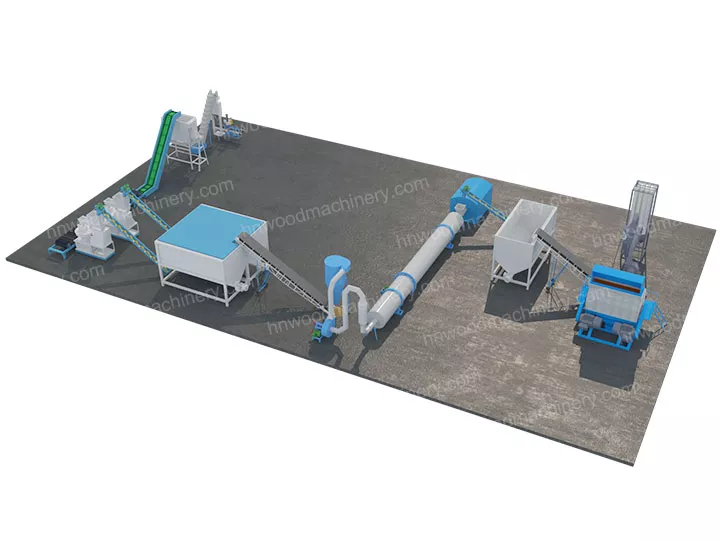

The wood pellet making machine is a device that transforms different types of crushed wood, plant straw, plant shells, and slag into biofuel pellets. The ring die pellet mill can produce up to 4000kg/h and is often utilized for large-scale production. The renewable fuel pellets it creates are smooth and dense, making it a top choice for many users.

Shuliy offers a variety of wood pellet making machines, each with different output capacities. Customers can choose from several models based on their needs. Besides these machines, we also provide smaller wood pellet machines for those with lower output requirements.

We aim to recommend the most suitable machines tailored to our customers’ specific needs. To enhance convenience and efficiency, we also supply feeding machines and conveyor belts, allowing for seamless and continuous operation.

Raw materials for wood pellet making machine

The wood pellet mill is capable of processing a variety of materials, primarily focusing on wood products like wood shavings, sawdust, branches, and logs.

Additionally, it can also handle other raw materials such as palm fiber, bagasse, peanut shells, corn stalks, wheat straw, and numerous agricultural wastes. These materials are readily available, cost-effective, and can be transformed into biomass pellets for various applications.

Usage of the finished wood pellets

Biomass pellets are primarily utilized in biomass power plants, biomass boilers, home heating, and various industrial applications. Therefore, investing in the biomass fuel sector to establish pellet production facilities presents significant market potential.

Structure of wood biomass pelletizer machine

The wood pellet making machine consists of several key components, including the feeding port, feeding cylinder, observation window, cover plate, motor, dust cover, discharging port, gearbox, and more. Its overall design is efficient, requiring minimal floor space while being robust, durable, and resistant to wear.

How does the wood pellet extruder work?

The raw material is introduced into the pellet mill via a screw feeder, which then directs it into the conditioner. In this stage, an adherent is added to help bind the particles together, facilitating the formation of dense and solid pellets.

After conditioning, the raw material moves into the pelletizing area. This section features a ring-shaped die, which is why this biomass pellet manufacturing equipment is referred to as a ring die pellet mill. Inside the ring die, there are two to four rollers. As the raw material enters this chamber, centrifugal force pushes it against the inner surface of the ring die. Typically, both the roller and the ring die rotate, compressing the raw material between their surfaces.

The compressed raw material extrudes through the holes of the ring die, emerging in the form of sticks. A knife-like slicer then cuts these sticks to produce pellets of the desired size, allowing for adjustments in pellet length according to specific requirements.

Wood pellet maker’s parameters

| Model | YGKJ380 | YGKJ450 | YGKJ560A | YGKJ560B | YGKJ560C | YGKJ700 | YGKJ880 |

| Capacity(T/H) | 0.2-0.3 | 0.6-0.8 | 1-1.3 | 1.2-1.5 | 1.2-1.5 | 2-2.5 | 3-4 |

| Power(KW) | 22+0.75 | 55+1.5+ 1.1+0.37+ 0.55 | 90+1.5+ 1.5+0.55+ 0.37 | 90+1.5+ 1.5+0.55+ 0.37 | 90+1.5+ 1.5+0.55+ 0.37 | 160+2.2+ 0.37+0.75 +1.5 | 220+3+0.5 5+2.2+1.1 |

Why is the ring die pellet mill popular with investors?

- Our wood pellet-making machine features a straightforward design, is highly adaptable, occupies a small space, and operates with minimal noise.

- Traditional energy sources are struggling to keep up with the demands of the global market, making biomass pellet fuel a viable alternative to coal.

- Powdered feed and grass powder can be granulated without the need for any added liquid. As a result, the moisture content of pellet feed remains very low, making it easier to store.

- The raw materials for a ring die pellet machine primarily include crop straw and similar materials. These inputs are inexpensive, resulting in a low cost per ton. Additionally, the machine boasts a high processing output. Given the significant market demand, this industry proves to be quite profitable.

Differences and suggestions between ring die and flat die pellet machines

There are two general types of biomass pellet mills. In addition to this machine, the other type is called a flat die pellet machine. Both of them have different designs, working principles, production capacities, and so on. But they have the same function – biomass pellet production.

- The output of a flat die pellet machine is typically between 1.5 to 3 kg while pellet-making machines can produce 0.2 to 0.3 tons. Therefore, if you’re looking for a higher output, it’s advisable to opt for a ring die pellet machine.

- There are different feeding methods to consider. In a flat die pellet machine, the material enters the pressing chamber vertically due to its weight. In contrast, the wood pellet-making machine uses a curved feeding trough that rolls and compresses the feed.

- When it comes to particle finish and compression ratio, the ring die granulator offers a wider adjustable range compared to the flat die pellet machine. The pellets produced by the ring die machine tend to have a smoother finish than those from the flat die machine. If you have specific requirements for the compression ratio and appearance of the granulated products, along with a need for higher output, a wood pellet-making machine would be the better choice.

Why choose Shuliy Machinery’s wood pellet mill?

Our biomass pellet machine is very popular. And many biomass pellet factories at home and abroad have chosen our machine. Now our machines have been sold to Uganda, the Philippines, Senegal, Malaysia, Mexico, Australia, and other countries.

- Shuliy is a skilled manufacturer of wood machinery, bringing years of expertise to the industry.

- We specialize in designing and customizing unique machinery tailored to meet the specific requirements of our diverse clientele.

- Our dedicated sales service team is available to provide professional assistance to customers both online and offline.

- Customers can conveniently make payments online and monitor their logistics, ensuring a confident purchasing experience.

- All components of our machines are crafted from high-quality, wear-resistant materials typically used in heavy machinery.

After examining the costs and profits associated with the biomass pellet processing industry, it becomes clear that the investment potential for the ring die pellet machine is quite significant, and there remains a healthy profit margin. If you want to join the biomass pellet processing industry or need to buy a ring die pellet machine, you can contact us at any time.