Wood Shredder Machine For Sawdust Making

| Model | SL-600 |

| Capacity | 1500-2000KG/H |

| Outlet size | 0.3-0.8cm |

| Power | 30kw |

| Model | SL-700 |

| Capacity | 2000-2500KG/H |

| Outlet size | 0.3-0.8cm |

| Power | 37kw |

You can now ask our project managers for technical details

The wood shredder machine efficiently transforms wood into sawdust or wood chips. This series of products is designed using principles of impact, shear, mutual impact, and grinding. It can achieve a maximum output of up to 4 tons per hour.

Initially, the machine cuts large pieces of wood before finely crushing them to ensure effective processing. This method significantly reduces the volume of wood waste, allowing it to be further processed into wood pellets or used as fuel in cogeneration or waste treatment plants.

There are five models in the wood shredder machine series, that can cater to the needs of most users. In terms of power, the wood crusher can operate using either an electric motor or a diesel generator. Additionally, to produce wood chips of varying fineness, we offer different sizes of screens.

The wood shredder machine resembles the hammer chip crusher and wood shavings machine. Therefore, we will recommend the machine that best fits our customers’ needs. If you have any questions, please don’t hesitate to reach out to us.

Our sawdust making machine features

- Thoughtful design enhances crushing efficiency by 50% over traditional models.

- Visually appealing, with a high output ranging from 400 to 2000 kg/h.

- Powered by a single motor, it offers energy savings and reduced costs.

- The crushed materials are suitable for pellet or briquette processing.

Wide application of wood shredder machine

The wood crusher is capable of efficiently breaking down various materials, including logs, branches, waste boards, and leftover wood from construction. It can handle all types and sizes of wood, making it perfect for grinding lumber, untreated wood, pallets, doors, slats, frames, and more.

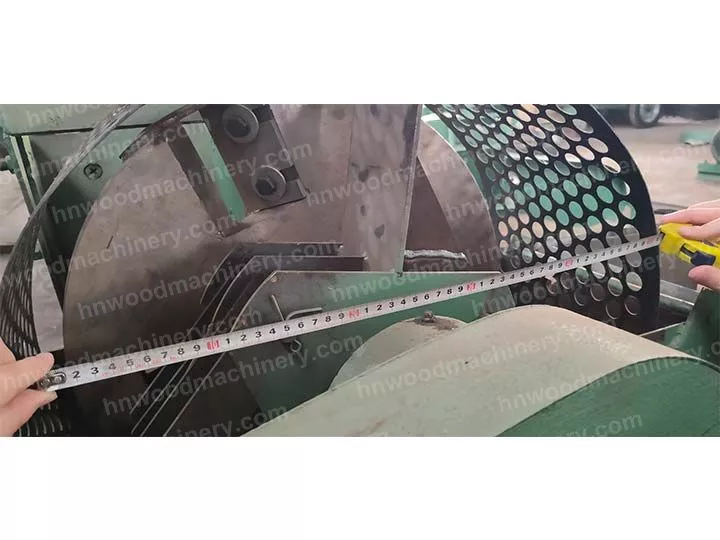

Structure of wood crushing machine

The wood crusher machine primarily consists of the following components: the machine base, the feeding port, the knife plate, the blade, the hammer blade, the machine shell, and the electric control cabinet.

Different sieves can create varying sizes of wood chips. When a sawdust-making machine operates, the material in the crushing chamber is finely crushed efficiently. You can choose the right size of the screen according to your needs.

Additionally, the wood shredder machine boasts high output, low energy consumption, and produces fine, uniform particles. Moreover, this equipment is characterized by low noise, minimal dust, no pollution, straightforward operation, low maintenance costs, and ease of use.

Display and use of finished products

Raw materials that can be processed by a wood crusher are diverse, but there are standard size requirements. Generally speaking, it can crush tree branches and stems with a diameter ranging from 70mm to 250mm. The resulting crushed materials are particles with a diameter of approximately 3-5mm.

The wood shredder machine is designed for various wood crushing and recycling tasks, including hardwood, softwood, particle board, plywood, and waste materials like sofas and wooden cabinets.

Additionally, it can handle bamboo chips, thatch, corn stalks, sorghum stalks, and other fibrous materials. It is also suitable for producing raw materials for particle boards, sawdust boards, and high-density boards.

Industrial wood crusher working principle

Wood is introduced through the inlet. As the blades cut and crush the material, the rotor creates a high-speed airflow that moves in the same direction as the blades. This airflow accelerates the material, causing it to be repeatedly impacted and crushed more thoroughly.

Simultaneously, this process increases the crushing rate of the material. Ultimately, the resulting wood chips are expelled by the high-speed vapor flow produced by the wind blade on the crushing knife plate.

Wood chipper shredder technical parameters

| Model | Capacity | Outlet size | Power |

| SL-420 | 600-800KG/H | 0.3-0.8cm | 7.5-11kw |

| SL-500 | 1000-1500KG/H | 0.3-0.8cm | 18.5kw |

| SL-600 | 1500-2000KG/H | 0.3-0.8cm | 30kw |

| SL-700 | 2000-2500KG/H | 0.3-0.8cm | 37kw |

| SL-900 | 2500-3000KG/H | 0.3-0.8cm | 55kw |

| SL-1000 | 3000-4000KG/H | 0.3-0.8cm | 75+7.5kw |

Different power modes are available

The wood sawdust making machine can be powered by electric motors, diesel engines, or diesel generator sets. You can select the option that best fits your local working conditions. We offer customization and will recommend the most suitable power solution based on your specific needs.

Mobile type wood shredding machine

We can attach wheels to the bottom of the machine to make it easier for users to move it to different locations.

Industrial wood shredder shipped to Mauritius

This customer has experience in importing and previously purchased two wood processing machines from China. Now, he is looking for another wood shredder machine to produce wood chips for chicken nesting. Based on the size and output of the logs he handles, we recommended the SL-1000 wood shredder.

The customer was pleased with the machine after using it for a while. Consequently, he decided to order one to launch his business of creating chicken nests using wood chips. Here’s a picture of the packaging and delivery of the industrial wood shredder. If you’re interested in wood processing machines, feel free to explore this website and reach out to us.