Biomass Pellet Machine Flat Die Wood Pellet Mill For Sale

| Model | 300 |

| Power(KW) | 22+0.37 |

| Output (kg/h) | 150-300 |

| Model | 400 |

| Power(KW) | 37+0.37 |

| Output (kg/h) | 200-500 |

| Model | 450 |

| Power(KW) | 55+0.37 |

| Output (kg/h) | 300-700 |

You can now ask our project managers for technical details

Our flat die biomass pellet machine is capable of producing wood pellets from various materials such as sawdust, recycled paper, grass, leaves, and other types of biomass. It’s commonly utilized in homes, small farms, and workshops.

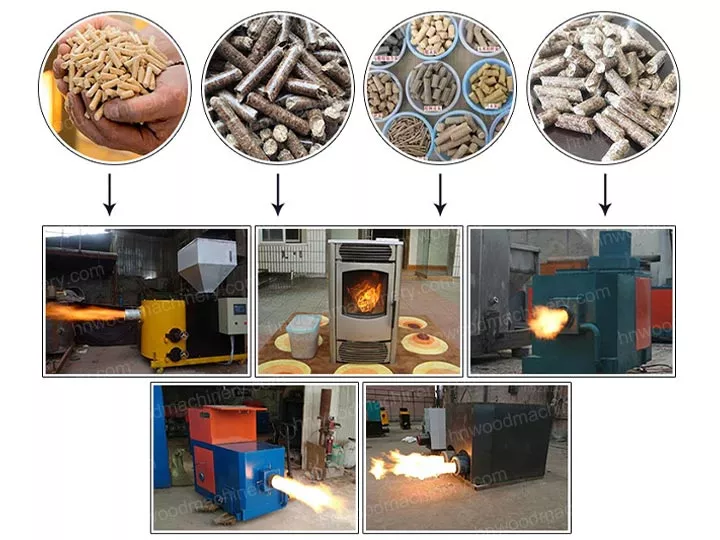

The pellets created can reach lengths of up to 3cm and are suitable for applications like home heating, cooking, and animal bedding. We offer a range of machine models to choose from, with production capacities of up to 700kg/h.

The diameter of the flat die hole, which determines the size of the wood pellet, can be tailored to meet your specific raw material and unique needs. We have achieved optimal compression ratios for over 30 different raw materials. If you have a special type of raw material, feel free to send it to us, and we will test it for you at no cost.

The mold and pressure wheel of the pellet mill are constructed from wear-resistant alloy steel, giving them qualities of strength, durability, and an extended service life. The biomass pellet machine features a straightforward design, broad applicability, and a compact footprint, and operates with low noise, making it an essential piece of equipment for many biomass manufacturers.

Applicable materials of wood pellet mill

The wood biomass pellet machine is suitable for a wide range of materials. It can be sawdust or crops, such as corn stalks, straws, peanut shells, corncobs, cotton stalks, weeds, etc. You can use a crusher machine to get sawdust raw material. (Read More: Wood Shredder Machine For Sawdust Making>>)

Biomass pellet fuel boasts a high calorific value, ranging from approximately 3900 to 4800 calories per kilogram. During combustion, the emission of harmful gas components is minimal, resulting in lower harmful gas emissions and providing environmental advantages. Additionally, the ash produced after burning can be utilized as potash fertilizer, offering cost savings.

Biomass pellet machine working principle

The wood pellet extruder machine operates using a motor (or diesel engine) that drives the gears, transferring power to the main shaft. As a result of the friction force, the pressure roller rotates, generating frictional heat between the pressure roller and the die, which helps to plasticize the powdery material.

The material is then pushed through the die hole by the pinch roller. Finally, the throwing tray transports the completed wood pellets out of the biomass pellet machine via the discharge port.

Finished wood pellets available for sale

Raw material collection → raw material drying → granulation and molding → bagging and sales.

Notes:

- Since the sawdust does not need to be crushed, the crushing link is omitted, and it can be granulated directly after drying.

- The moisture content after drying should be 15-18%. If the moisture content is too large or too small, it is not conducive to the formation of particles.

Features of wood pellet making machine

- The material is dry and dries out without losing moisture. It features differential gear, universal joint transmission, low energy consumption, and high output.

- This wood pellet making machine utilizes advanced technology for extrusion granulation and polishing, effectively addressing the challenges of granulation found in traditional methods.

- The resulting sawdust particles are uniform, smooth, and round, exhibiting high strength and excellent fluidity.

- The rollers and molds, often referred to as plates or disks, are constructed from a highly wear-resistant alloy steel that undergoes special heat treatment to achieve high hardness and extended durability.

- The transmission gears are crafted from high-quality alloy steel, offering benefits such as smooth operation, low noise levels, high load capacity, minimal temperature increase, and excellent pressure resistance.

- This biomass pellet machine has a wide range of applications. It can be employed for the re-granulation of organic waste in biomass fuel plants, power plants, animal husbandry, feed mills, and various other industries.

Wood sawdust pellet machine parameters

| Model | 300 | 400 | 450 |

| Power(KW) | 22+0.37 | 37+0.37 | 55+0.37 |

| Output (kg/h) | 150-300 | 200-500 | 300-700 |

In addition to this flat die biomass pellet machine, we also produce ring die biomass pellet machines. (Related Post: Wood pellet making machine丨wood pellet mill for sale>>)

How to start a biomass pellet manufacturing business?

As an environmentally friendly renewable fuel, biomass pellets are mainly used to replace coal, natural gas, etc., and their production business is attracting more and more investors. So, what should you pay attention to if you also plan to carry out this project?

- What is the purpose of the pellets you want to create?

- How many pellets are you aiming to produce?

- What raw materials do you plan to use?

- What is your budget for this project?

Our factory has been specialized in the manufacture of wood processing and recycling machinery for many years. If you are engaged in this business, then we are your best choice. Please browse this website, encourage everyone to consult at any time, and welcome to visit our factory. We look forward to cooperating with you.