Pallet Block Making Machine Wood Sawdust Block Forming Equipment

| Size | 90*90mm (Customizable) |

| Motor | 15-18kw |

| Capacity | 4 m³/24h (different for different materials) |

| Density | 550-600kg/m³ |

| Material consumption | 550-600kg/m³(wood shavings, sawdust) |

| Glue consumption | 80-100kg/m³ |

| Temperature control | PID |

| Dimension | 4800*760*1300mm |

| Weight | 1300 Kg |

You can now ask our project managers for technical details

The pallet block making machine is specialized in producing dragging tray matting foot and protective layer matting blocks, used for transportation and storage. It can process about 4m³ of raw materials per day. The density of the final product can reach 550-1000kg/m³.

We can customize the shape and size of the finished wood block, ranging from 75 mm to 145 mm. Our pallet block making machine can produce two types of wood blocks, solid and hollow. You can choose according to your needs.

Shuliy’s pallet block making machine can produce high-quality wood blocks using wood sawdust as raw material. The finished products do not have any loose scraps and exhibit good water resistance. This machine has been well-received by numerous customers.

Additionally, we offer two types of sawdust block making machines: one is the common model and the other is the European standard model. The European standard machine is slightly more expensive. However, there are differences between the two machines. If you are interested, please contact us for further information.

Raw materials used in sawdust block-making machine

The raw materials used in the sawdust block making machine are generally wood sawdust, wood chips, wood shavings, etc., similar to the raw materials used in the press wood pallet making machine.

Two types of wood blocks

There are two types of wood blocks we produce: solid and hollow. But we recommend the hollow blocks because they are breathable, allowing heat to dissipate and preventing moisture buildup.

The sizes of sawdust wood blocks

General size: 80*80mm, 90*90mm, 100*100mm.

European standard size: generally above 100mm, for example, 145*105mm.

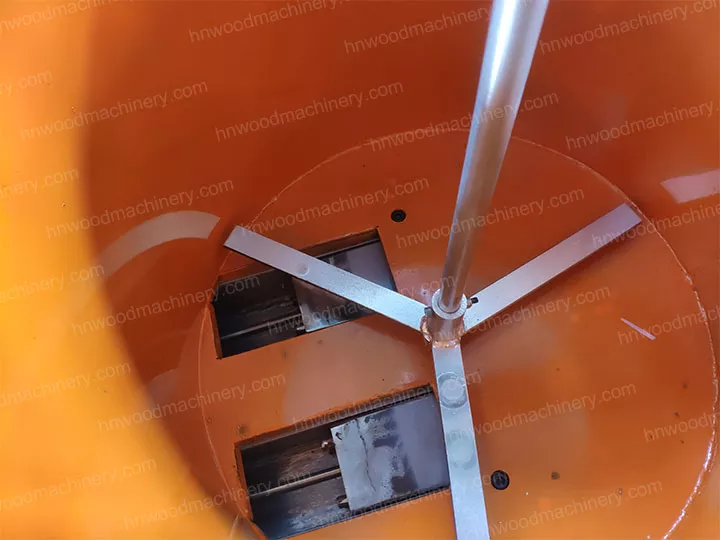

Sawdust wood block hot press machine structure

Pallet block making machine contains an electric control cabinet, hopper, hydraulic pushing device, heating and forming device, outlet (with double outlet and triple outlet), saw (manual or automatic), etc.

Sawdust block forming machine parameters

| Size | 90*90mm (Customizable) |

| Motor | 15-18kw |

| Capacity | 4 m³/24h (different for different materials) |

| Density | 550-600kg/m³ |

| Material consumption | 550-600kg/m³(wood shavings, sawdust) |

| Glue consumption | 80-100kg/m³ |

| Temperature control | PID |

| Dimension | 4800*760*1300mm |

| Weight | 1300 Kg |

Working principle of pallet block machine

- The hydraulic cylinder generates high pressure, driving the piston to extrude and shape the materials.

- The heating plate, set to a high temperature, aids in the solidification and molding of urea-formaldehyde glue.

- The material is then cut to a specific length, typically around 1.2 meters.

- After cooling, the long wood strips of semi-finished products are cut down to their final size.

Machines work together with sawdust block maker

The sawdust block making machine can be combined with a crusher, airflow dryer (with the furnace), gluing mixer, woodblock cutter, etc. to form a production line. We can match the production line of the wood block machine according to the customer’s actual situation.

Benefits of sawdust block making machine

- There are various types of sawdust block making machines, which can meet different customers’ needs.

- The good working effect, beautiful, clean, and durable briquettes produced.

- The pallet block making machine is durable and has a long service life.

- Easy to use, with an electric control cabinet, and easy to operate.

- Easy to operate, one person can operate 3 machines.

- The machine can effectively recycle wood waste.

What are advantages of sawdust wood blocks?

- Because the wood block is formed through high-temperature extrusion, it is free from fumigation.

- Low production cost. The wooden mat block consists of wood chips, and the raw material is cheap and easy to obtain.

- High load-bearing performance. It can support most items and is widely used.

Our factory has been producing wood processing equipment for many years and has rich experience. If you are engaged in this industry, you may wish to browse this website and feel free to contact us. We will be your best choice.