Drum Wood Chipper Commercial Timber Chips Making Machine

| Model | SL-218 |

| Knife Quantity | 2 |

| Feeding size | 300*680 mm |

| Capacity | 10-15 t/h |

| Raw material dimension | ≤300 mm |

| Wood chip size | 25 mm(Adjustable) |

| Main power | 110 kw |

| Weight | 8600 kg |

| Feeding inlet conveyor | 6 m |

| Outlet conveyor | 8 m |

| Packing Size | 3105*2300*1650 mm |

You can now ask our project managers for technical details

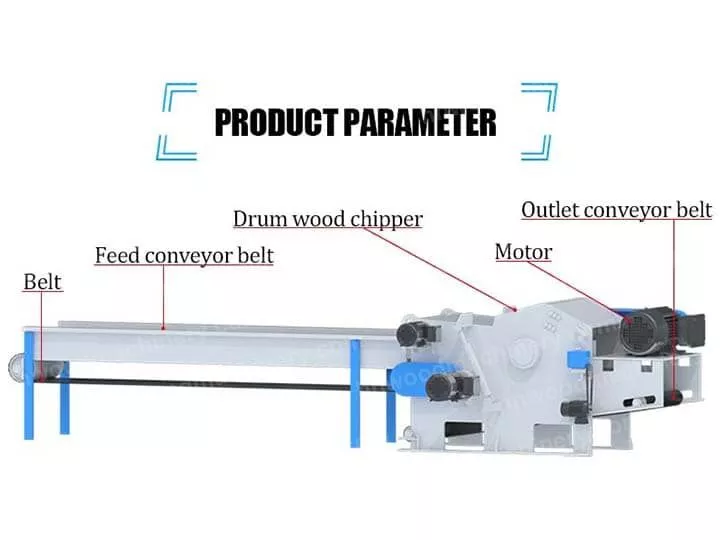

The drum wood chipper is equipped with an advanced cutting system. It can easily handle logs and branches of various hardnesses for precise and fast chipping operations, with a processing capacity of up to 15 tons of wood per hour.

Due to the high output of this machine, it is generally used in medium and large wood processors. The wood chips are generally used for rough crushing before wood crushing, paper making, fuel, and making all kinds of boards, etc.

The drum chipper is equipped with a conveyor belt for automatic feeding, which significantly reduces both time and labor requirements. Moreover, the pressure rollers in the drum chipper actively push the material into the chipping system.

This machine can be integrated with a conveyor belt and a hammer mill to create a complete production line for processing wood chips. Additionally, we also manufacture smaller small wood chippers.

Raw materials: this drum wood chipper machine is capable of processing various materials such as maidenhood, lumber, logs, and small-diameter wood. (Please note that the materials used with this machine should not contain nails).

Application scope of wood chips: the wood chips produced can be utilized for making paper, manufacturing particle board, and fiberboard, or as fuel. Additionally, we can sell the wood chips directly.

Unique benefits of industrial wood chipper

- Strong working. It can process various materials efficiently. The final product processing is good.

- Long service life of the machine: the machine’s knife roll, knife plate, and blades are all made of high-quality materials, which are wear-resistant and durable.

- The drum wood chipper has an independent electric control cabinet, so the machine is safe to use and easy to operate.

- The chipper can automatically adjust the size of the feeding port. According to the different thicknesses of the raw material, the upper feeding roller can float up and down within a certain range with the help of a hydraulic system.

Internal structure of drum wood chipping machine

Drum wood chipper mainly includes the body, knife roller, feeding and unloading mechanism, hydraulic system, feeding device, and other parts.

- Body: all welded with high-strength steel plate, which is the support base of the whole machine.

- Knife roller: there are several flying knives installed on the knife bar. And we fix the flying knives on the knife roller through the pressure block.

- Hydraulic system: the oil cylinder is supplied by the oil pump, which can start the cover and facilitate the blade replacement. The upper feeding roller assembly can be lifted during maintenance, which makes it easy to adjust the gap between the flying knife and the bottom knife.

- Up-and-down feeding mechanism: it is composed of a feeding interface, an up-and-down feeding roller, and a feeding gap adjustment mechanism. The wood entering from the feeding interface is pressed by the upper and lower feeding rollers and fed into the chipping mechanism at a certain speed.

Large commercial wood chipper specifications

| Model | SL-218 | SL-216 |

| Knife quantity | 2 | 2 |

| Feeding size | 300*680 mm | 230*500 mm |

| Capacity | 10-15 t/h | 5-8t/h |

| Raw material dimension | ≤300 mm | ≤230 mm |

| Wood chip size | 25 mm(Adjustable) | 25 mm(Adjustable) |

| Main power | 110 kw | 55 kw |

| Weight | 8600 kg | 5600 kg |

| Feeding inlet conveyor | 6 m | 6 m |

| Outlet conveyor | 8 m | 8 m |

| Packing size | 3105*2300*1650 mm | 2735*2200*1200 mm |

How does this wood chips making machine work?

The wood is fed through the feed port and when it comes into contact with the cutting blade, it is cut following the high-speed rotation of the cutting blade.

The cutting mechanism is a rotating drum wheel with several flying knives mounted on it. The knives rotate to process the wood into pieces.

There are several square holes on the outer edge of the drum wheel, and the cut pieces of qualified material fall through the mesh screen holes and are discharged from the bottom. The larger pieces of material will be cut again in the woodchipper machine.

Why choose Shuliy’s drum wood chipper?

- Newly designed blade rotor, the blades are easy to change.

- The crushing chamber cover can be opened hydraulically for easy maintenance and blade replacement.

- Screen size can be customized according to different requirements of final product size. The hydraulic buffer system ensures smooth operation.

- Reverse feeding device, the belt machine can be reversed to advance. This device can protect the machine when encountering large pieces of wood.

- Larger capacity and larger feed size than traditional models, can cut logs with a diameter of 230-500mm.

Our factory has specialized in the production and manufacturing of wood processing machinery for many years, gaining rich experience and advanced technology. We sincerely invite you to consult with us at any time and warmly welcome you to visit our factory. We look forward to cooperating with you.