Shavings For Animal Bedding Good Price Wood Shaving Machine

| MODEL | SL-1000 |

| CAPACITY | 1500KG/H |

| INPUT SIZE | 20cm |

| POWER | 55kw |

| MODEL | SL-1200 |

| CAPACITY | 2000KG/H |

| INPUT SIZE | 24cm |

| POWER | 55kw |

You can now ask our project managers for technical details

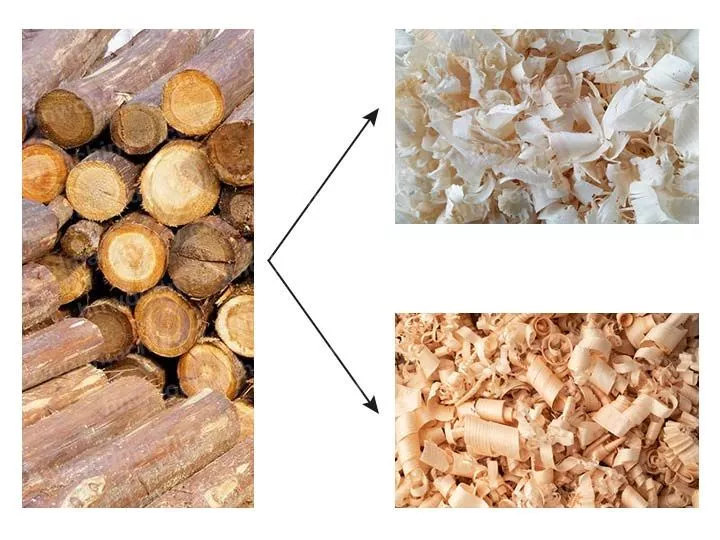

The wood shaving machine is specially designed to shave round log wood of different diameters into good quality wood shavings for animal bedding. It operates by rotating its blade to produce ultra-fine chips with a precision of up to 0.5 mm.

It can handle up to 3,000 kg of logs each hour, which helps to lower energy consumption in the production process by 20%. Whether used in furniture manufacturing, board production, or the pre-treatment of building materials, it contributes to improved production efficiency.

The finished shavings have adjustable sizes and can be used as bedding for livestock breeding and reproduction such as horses, pigs, cattle, sheep, chickens, pets, etc. It is very beneficial for the horse breeding industry, animal husbandry, or animal breeding industry.

Customizable machine shavings for animal bedding

Shuliy’s wood shaving machine has different models. We can meet the needs of more customers. We can also customize the machine according to the specific needs of our customers.

For example, we can raise the frame of the shavings for animal bedding and add two big wheels to facilitate customers to move the machine, etc. The depth of the knife can be adjusted as needed to obtain shavings of different thicknesses.

Regarding the power, the machine can be equipped with a diesel engine and electric motor. The countries we often export to are South Africa and the surrounding areas.

Before making shavings, you can pre-treat the logs with our log debarker.

Application scope of wood shaving machine

Raw material: logs (better after peeling), branches, etc.

Application of finished products

- It can be made into particle board (plywood), used as raw material for wood pulp paper in paper mills, and used as filling for fragile goods transportation in transportation companies.

- It is also used as filling for small-scale pigs, cattle, sheep, and various animals in their nests, and as bio-energy.

- This machine is used by small and medium-sized enterprises, as well as individual wood processing households such as particle board factories, board-making factories, paper mills, bio-energy fuel, pet bedding, poultry breeding for bedding nests, and logistics fragile bedding.

- It is also used in mushroom planting and growing bases.

Technical information on industrial wood shaver machine

| MODEL | CAPACITY | INPUT SIZE | POWER |

| SL-420 | 300KG/H | 6cm | 7.5kw |

| SL-600 | 500KG/H | 12cm | 15kw |

| SL-800 | 1000KG/H | 16cm | 30kw |

| SL-1000 | 1500KG/H | 20cm | 55kw |

| SL-1200 | 2000KG/H | 24cm | 55kw |

| SL-1500 | 2500KG/H | 32cm | 75kw |

Structure of pine wood shavings making machine

The pine wood shaving machine mainly includes the frame, feeding port, knife plate, blade, screen, discharge port, etc. Generally, the small size of the shaving machine also comes with Shakelong, which can concentrate the dust produced by the machine when working. We can also raise the frame and install the wheels according to the customer’s requirements.

How does the wood log shaver machine work?

After the raw material enters the feeding port, it will be crushed by the impact of the high-speed rotating hammer. The shearing knife will then cut it into the crushing chamber.

Then the wind generated by the built-in wind blade will be sent to the material outlet through the screen, or an external fan will be used to pump the wind to the material outlet.

The size of shavings is determined by adjusting the blade length and screen aperture size to meet various needs.

Disk wood shaving machine’s knife and blade

- The shavings system is the most important part of the machine, which contains the knife plate and the blade.

- The cutter disc and blade we produce are made of high-quality material, strong and durable, sharp, and provide a good shaving effect.

- In addition, the number of blades varies from model to model, with options of four blades and eight blades.

- The tilt of the blade can be adjusted to control the thickness of the shavings.

Highlights of commercial wood shaving mill

- The commercial wood shaving machine has a reasonable layout, easy installation, convenient operation, and maintenance.

- Safe, durable knives and low noise.

- Reasonable design, made of high manganese steel, compact structure.

- Driven by only one motor, it has high efficiency and high-cost performance.

- Shavings for animal bedding have a fast production speed, saving a lot of time and manpower.

- The finished shavings produced are thin, soft, and good in texture.

- The contact pressure between the wood and blade remains constant, and the reciprocating speed of the wood also remains constant, producing shavings of uniform thickness.

Successful case

The customer is from Abkhazia and is a purchasing manager of a lumber mill. He contacted us after watching our YouTube video. Through communication, the customer expressed the need for a larger type of shaving for animal bedding.

Our sales manager provided the customer with pictures, videos, and parameters of the larger wood shaving machine. Finally, the customer chose the SL-800 model with a capacity of 1000KG/H. After that, we promptly provided the PI of the machine. The customer was satisfied and placed an order for the shaver after seeing it.

Our service

We provide a set of spare parts and packaging. All machines are tested before shipment. In addition, the machines are packed in standard export wooden boxes, and our long-term cooperative transportation company will ship them on time and safely.

For after-sales service, we provide a one-year warranty period, and you can buy spare parts from us. At the same time, we can provide professional consultation and problem solutions.