Log Debarker Machine For Wood Timber Peeling

| Model | SL-300 |

| Max diameter | 300mm |

| Knife quantity(pcs) | 4 |

| Main power(kw) | 7.5 |

| Driving power(kw) | 1.5 |

| Weight(T) | 1.5 |

| Size(L*W*H)(m) | 2.5*1.8*1.1 |

You can now ask our project managers for technical details

The wood log debarker machine utilizes cutting-edge rotary debarking technology equipped with high-strength alloy blades to effectively debark logs. It can process up to 20 tons of logs per hour, boosting efficiency by over 30% compared to conventional equipment.

With its precisely controlled peeling depth and automatic adjustment system, each piece of wood achieves uniform and damage-free peeling, while also reducing energy consumption by as much as 20%.

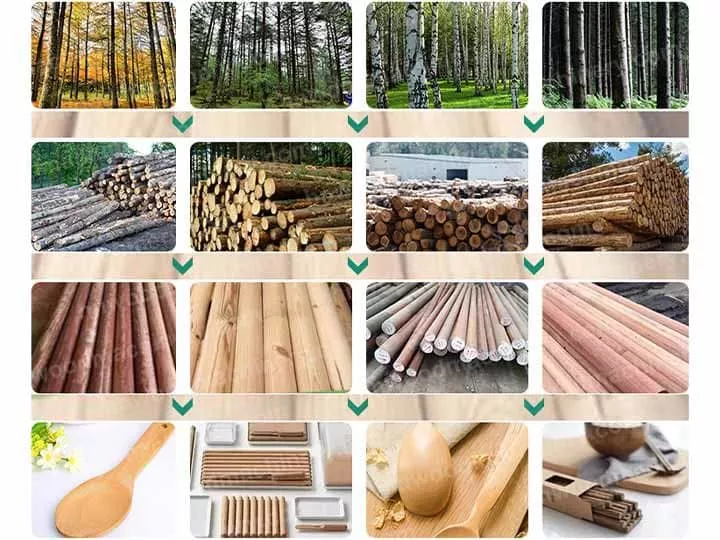

Generally speaking, the wetter the bark of the wood is, the better the effect of the machine. The treated wood can be further processed in various ways, such as cutting wood, shaving, crushing, etc.

Available wood log debarker machine

Our factory produces two types of wood peeling machines: one is a small vertical wood peeling machine, and the other is a large horizontal wood peeling machine. Their barking methods and output differ, allowing customers to choose the machine that best suits their needs.

Since our establishment, we have frequently exported the log debarker machine to various countries, including the United States, European countries, South Africa, and Australia. Our customers have developed long-term relationships with us due to the machine’s low price, durability, and effective performance.

Using scopes of wood timber peeling machine

The log debarker machine is suitable for debarking freshly cut coniferous woods and some hardwoods, as well as debarking frozen and dry woods.

It is widely used in paper mills, pulp mills, wood chip mills, forestry, fuel pellet producers, and other wood processing enterprises, such as sawmills and artificial board mills (plywood mills, MDF mills).

Additionally, the wood peeling machine is highly suitable for assembly line operations and is an essential piece of equipment in automated production.

Type 1: Vertical wood peeling machine

The output of the vertical wood peeling machine is relatively small. This type of log debarker machine is suitable for processing logs, trunks, sections, and other wood. It allows wood bending up to 8% and trunk diameter in the range of 5-35cm.

The fresher the trunk, the higher the barking efficiency and the better the barking effect. As for the power source, it can be either an electric motor or a diesel engine. Customers can choose according to their needs.

Structure of high-speed wood peeling machine

A vertical wood peeling machine, also known as a ring-type wood peeling machine, is primarily made up of a feeding mechanism, discharging mechanism, knife plate, transmission system, and bottom frame, along with other parts. This design allows for easier feeding.

Additionally, we weld a long channel and bracket at the feed opening. Furthermore, shelves and wheels can be installed on the log debarker machine based on the customer’s requirements, making it convenient for transportation.

Technical parameter of small log debarker

| Model | SL-260 | SL-300 |

| Max diameter | 260mm | 300mm |

| Knife quantity(pcs) | 4 | 4 |

| Main power(kw) | 7.5 | 7.5 |

| Driving power(kw) | 1.5 | 1.5 |

| Weight(T) | 1.2 | 1.5 |

| Size(L*W*H)(m) | 2.2*1.3*1.1 | 2.5*1.8*1.1 |

How does the industrial log debarker work?

The industrial log debarker adopts step-less variable speed technology to automatically adjust the feeding speed. This allows it to be suitable for peeling various kinds of wood with different species, diameter grades, and curvatures.

The ring-type debarker uses a rotary cutting working principle with a ring knife. Each wood is peeled and treated individually, resulting in a better and more thorough treatment effect.

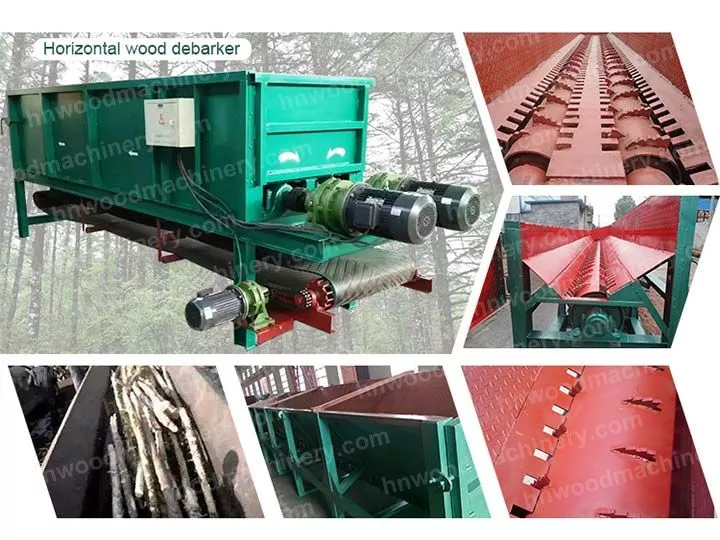

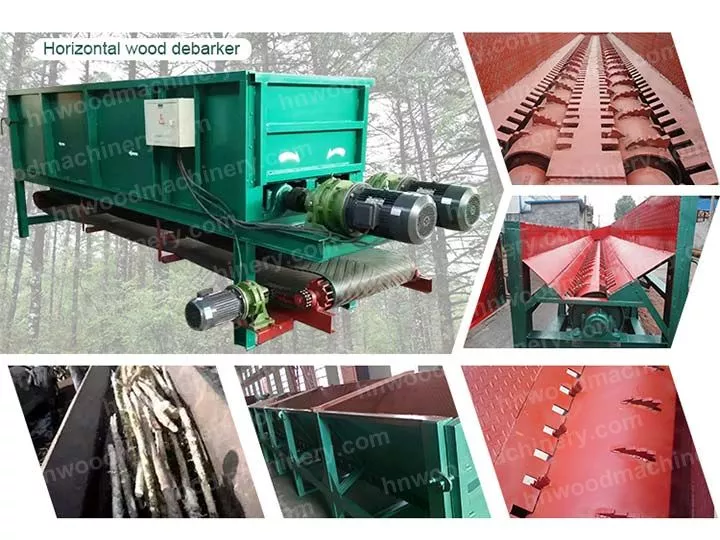

Type 2: Horizontal wood peeling machine

A horizontal wood peeling machine, also known as a trough-type wood peeling machine, has a high output. It can process various species, shapes, and lengths of wood in batches.

The diameter of the material to be processed by the log debarker machine should be less than 30 cm. By using grippers and mesh belt conveyors in conjunction with the machine, it can operate more efficiently and save a significant amount of manpower.

Structure of horizontal wood skinning machine

The structure of the trough-type skinning machine is simple. The log debarker machine mainly includes a frame, skinning mechanism, transmission system, baffle, rotor with skinning teeth, and power unit.

Detailed information on the log peeler

| Model | SL-700 | SL-800 |

| Max diameter | 400 | 500 |

| Wood length(m) | 2-5 | 2-6 |

| Capacity(T/H) | 10-12 | 15-18 |

| Power(kw) | 11*2 | 15*2 |

| Weight(T) | 3.5 | 6 |

| Size(L*W*H)(m) | 6*2.5*1.6 | 6*2.8*1.7 |

Working principle of double roller wood peeling machine

A double roller wood peeling machine utilizes the unique force generated by the rotor with barking teeth to move the wood section in the silo slot plate cycle.

It also causes the wood section to rotate around its axis and perform irregular jumping. As a result, there is continuous friction between the wood section and teeth, as well as between the wood section and barn slot, which achieves an efficient peeling effect.

Features of wood log debarking machine

- The wood debarking machine has a wide range of applications and can handle various sizes and species of wood.

- It has a high peeling rate, reaching an efficiency of over 95%.

- The machine is simple and convenient to operate, with only one employee needed to complete all the peeling work.

- It has low energy consumption and a low failure rate, as well as a long service life. The machine can be used on the ground without additional installation, making it easy to use.

- Both machines have high efficiency and can operate continuously. The horizontal debarking machine can handle a large amount of wood at once.

Characteristics of both wood peeling machines

- Vertical wood peeling machines generally handle relatively large wood diameters. However, the best raw materials should not be too bent. The machine requires employees to continuously feed the wood into it.

- Horizontal wood peeling machines can handle bending and smaller-diameter wood. These machines can process multiple materials in bulk at once. They are usually used in conjunction with gripping clamps and conveyor belts. Their high working efficiency meets the requirements of medium and large wood processing plants.

Successful case

Our customer from America owns a sawmill. He sent us a direct inquiry for a log debarker machine. After communication, we understood that the customer needed to process coarser logs. So we provided the customer directly with pictures and videos of the largest model of the peeling machine. The customer also indicated that the machine met the requirements.

Then our salesperson provided a quotation to the customer. After the customer confirmed all the details of the machine. The customer placed the order and we prepared the machine for production. After that, the machine is shipped to the destination.

Why choose Shuliy log debarker?

- Shuliy Machinery is a professional manufacturer of wood machinery. We can provide customers with favorable prices and high-quality machines.

- We can solve most of the problems encountered by customers promptly. We have a deep knowledge of wood machinery and can provide information on any aspect that customers want to know.

- We have extensive experience in exporting and can assist customers in resolving export-related issues promptly.

- Our machines have been exported to numerous countries, and all customers are satisfied with our machines.

We also have wood sawmill machines and sawdust making machines. The log debarker machine can be used for woodworking projects and is also ideal for farmers and log users. We sincerely invite you to consult at any time to learn more detailed information about wood processing machines and welcome you to visit our factory. We look forward to cooperating with you.