Industrial Wood Peeling Machine Solution for Chilean Clients

Recently, Shuliy wood peeling machine was successfully manufactured and shipped to Chile, marking another successful application of our wood processing solutions in the South American market.

This Chilean customer is engaged in wood processing and log pre-treatment, primarily handling natural logs used to produce products such as wood chips, lumber, or biomass fuel.

Efficient bark removal before processing is a crucial step in improving product quality, protecting downstream equipment, and increasing overall production efficiency.

Customer provides project information

Based on detailed discussions, the customer’s raw materials include:

- Logs with diameters ranging from 9 to 32 centimeters

- Mixed hardwood logs with natural bark

The local industrial power standard is 380V, 50Hz, three-phase. The customer places particular emphasis on high debarking efficiency, blade durability, and low maintenance costs, especially considering the long-term operation of the equipment.

Shuliy’s solution design

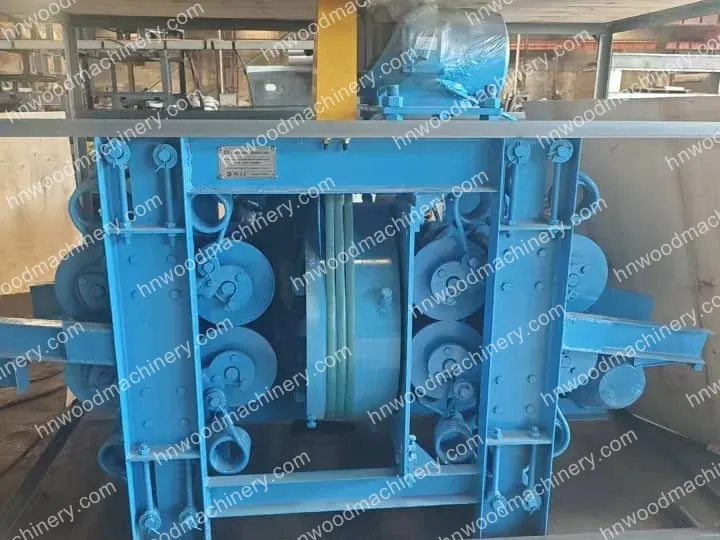

After evaluating the customer’s raw material dimensions, production requirements, and power supply conditions, we recommended the SL-370 wood peeling machine and modified the design to adapt to the voltage used in the local factory in Chile.

Below are the technical specifications of the modified SL-370 wood debarking machine:

| Model | SL-370 |

| Power | 11 kW + 4 kW |

| Voltage | 380 V, 50 Hz, 3-phase |

| Suitable log diameter | 9–32 cm |

| Dimensions | 2.3 × 1.25 × 1.83 m |

| Weight | 1500 kg |

| Blades | 5 pieces |

| Bearings | 4 pieces |

Reasons we recommend this model of wood debarking machine

The main reasons for choosing the SL-370 wood debarking machine are as follows:

- This wood peeling machine efficiently debarks logs with diameters ranging from 9 to 32 cm, handling customers’ mixed raw materials without frequent adjustments.

- The dual-motor configuration (11 kW + 4 kW) ensures powerful output, smooth rotation, and consistent debarking performance.

- Equipped with 5 high-strength debarking blades, the machine effectively removes bark while minimizing wood loss.

- Four high-quality bearings ensure long-term stable operation, which is crucial for industrial-scale production.

Contact us for a customized solution

This successful shipment to Chile further demonstrates our expertise in providing reliable, efficient, and customized wood debarking machine solutions to customers worldwide.

Whether you are a small workshop or a large industrial timber processing plant, we are committed to matching you with the most suitable equipment based on your specific raw materials and production goals.

Contact us for expert advice, technical support, and factory-direct pricing of the wood peeling machine. We are ready to help you improve efficiency and maximize your timber processing profits.