3 Tipos de Desencoladores de Madera: Soluciones Eficientes para el Procesamiento de Madera

Med den växande globala efterfrågan på högkvalitativt timmer och plywood har Shuliy Machinery officiellt introducerat en ny serie träborttagningsmaskiner, som erbjuder tre modeller: grovtyp, vertikal typ och horisontell typ, vilka uppfyller olika produktionsbehov inom träbearbetningsindustrin.

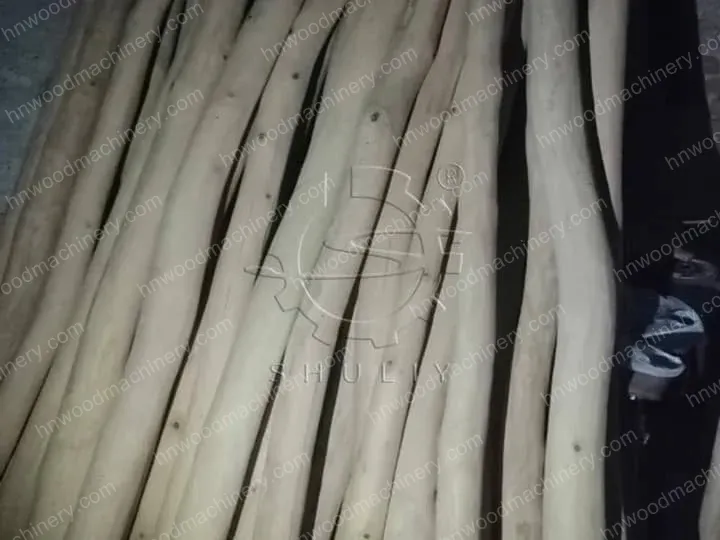

Dessa maskiner är utformade för att effektivt ta bort bark från stockar samtidigt som träets yta bevaras, vilket hjälper sågverk, fanervårdslver och möbelproducenter att öka produktiviteten.

Groove-typ träskalningsmaskin

Vår trough-borttagningsmaskin har en U-formad arbetskanal, vilket tillåter kontinuerlig bearbetning av flera stockar.

Fördel: Träborttagningsmaskinen erbjuder hög effektivitet och är lämplig för bearbetning av regelbundet formade stockar. Den ger jämn avverkning, minimerar barkrester och har ett bekvämt utsäde-system. Den är idealisk för storskaliga sågverks- och batchstockborttagningslinjer.

Vertikal träskalningsmaskin

Den vertikala roterande skalningsmaskinen har en vertikal matningsdesign och är idealisk för små träblock eller medelstora stockar.

Fördel: Denna träborttagningsmaskin har en kompakt footprint, vilket gör den lätt att underhålla med låg energiförbrukning. Dess stabila skalningshastighet säkerställer en konsekvent yta, så den är lämplig för små och medelstora möbel- och fanerbearbetningsanläggningar.

Mashine ya kusaga kuni ya usawa

Den horisontella träborttagningsmaskinen antar ett valsmatningssystem som hanterar långa eller tjocka stockar smidigare.

Fördel: Denna typ av stockborttagningsmaskin erbjuder stark barkborttagningskraft, vilket är lämpligt för träslag av hårdare sort. Dess kontinuerliga matningssystem säkerställer hög avverkning och exceptionell hållbarhet. Det är därför den ofta används i industriell plywood- och tungt träbearbetning.

Hur man väljer rätt träborttagningsmaskin för din träverksamhet?

- Fanya iwe wazi kuhusu aina na ukubwa wa mbao yako. Mbao laini kama poplar au mparacho ni bora zaidi kwa mashine za wima au za mifereji, wakati mbao ngumu kama eukaliptusi au acacia ni bora zaidi kwa mashine za usawa.

- Utvärdera produktionsskala. Små verkstäder väljer vertikala maskiner för utrymmessparande och kostnadseffektivitet. Medelstora anläggningar kan välja trough-typ maskiner, som kan bearbeta flera stockar samtidigt. Storskaliga industrier väljer horisontella maskiner för kontinuerlig, automatiserad matning.

- Fokusera på hållbarhet och eftermarknadsstöd. Välj en tillverkare som erbjuder robusta stålkonstruktioner, reservdelstillgång och tekniska tjänster. Det är bra att välja en ursprungstillverkare med egen fabrik för prisvärda priser och garanterad kvalitet.

Vad kan Shuliy erbjuda dig?

- Vi erbjuder ett omfattande produktsortiment. Oavsett om du vill köpa en enda borttagningsmaskin eller bygga din egen logskalningsproduktionslinje har vi professionell personal som hjälper dig att utforma den mest lämpliga lösningen.

- Med över ett decenniums global export erfarenhet har vi levererat till Afrika, Sydostasien, Mellanöstern och Europa, vilket säkerställer smidig logistik och sinnesfrid.

- Vi har vår egen fabrik som erbjuder oöverträffad kvalitet till konkurrenskraftiga priser och säkerställer pålitlig eftermarknadservice.

Shuliy’s tre träborttagningsmaskiner (trog, vertikal och horisontell) kan möta olika behov, från små verkstäder till stora industriella produktionslinjer. Om du är intresserad av specifika priser, vänligen kontakta oss!