Máquina trituradora de madeira para fabricação de serragem

| Modelo | SL-600 |

| Capacidade | 1500-2000kg/h |

| Tamanho da saída | 0,3-0,8cm |

| Poder | 30 kW |

| Modelo | SL-700 |

| Capacidade | 2000-2500kg/h |

| Tamanho da saída | 0,3-0,8cm |

| Poder | 37 kW |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

A máquina trituradora de madeira transforma madeira com eficiência em serragem ou lascas de madeira. Esta série de produtos foi projetada usando princípios de impacto, cisalhamento, impacto mútuo e retificação. Pode atingir uma produção máxima de até 4 toneladas por hora.

Inicialmente, a máquina corta grandes pedaços de madeira antes de triturá-los finamente para garantir um processamento eficaz. Este método reduz significativamente o volume de resíduos de madeira, permitindo que estes sejam posteriormente transformados em pellets de madeira ou utilizados como combustível em unidades de cogeração ou de tratamento de resíduos.

Existem cinco modelos na série de trituradoras de madeira, que podem atender às necessidades da maioria dos usuários. Em termos de potência, o triturador de madeira pode funcionar com motor elétrico ou gerador a diesel. Além disso, para produzir cavacos de madeira de finuras variadas, oferecemos diferentes tamanhos de telas.

A máquina trituradora de madeira assemelha-se ao triturador de lascas de madeira e à máquina de aparas de madeira. Portanto, recomendaremos a máquina que melhor se adapta às necessidades dos nossos clientes. Se você tiver alguma dúvida, não hesite em entrar em contato conosco.

Nossa máquina para fazer serragem apresenta

- O design cuidadoso aumenta a eficiência de britagem em 50% em relação aos modelos tradicionais.

- Visualmente atraente, com alto rendimento variando de 400 a 2.000 kg/h.

- Alimentado por um único motor, oferece economia de energia e redução de custos.

- Os materiais triturados são adequados para processamento de pellets ou briquetes.

Ampla aplicação de máquina trituradora de madeira

O triturador de madeira é capaz de quebrar com eficiência vários materiais, incluindo toras, galhos, tábuas de resíduos e sobras de madeira da construção. Ele pode lidar com todos os tipos e tamanhos de madeira, tornando-o perfeito para lixar madeira serrada, madeira não tratada, paletes, portas, ripas, molduras e muito mais.

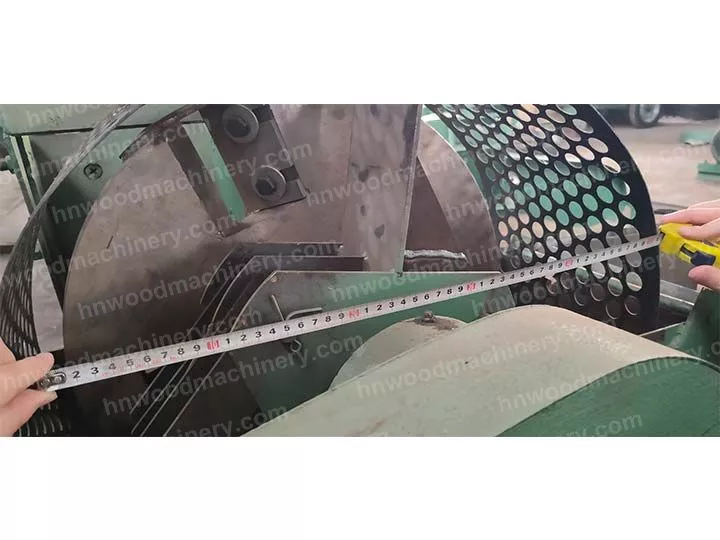

Estrutura da máquina trituradora de madeira

A máquina trituradora de madeira consiste principalmente nos seguintes componentes: a base da máquina, a porta de alimentação, a placa da faca, a lâmina, a lâmina do martelo, a carcaça da máquina e o gabinete de controle elétrico.

Peneiras diferentes podem criar cavacos de madeira de tamanhos variados. Quando uma máquina de produção de serragem opera, o material na câmara de britagem é triturado de forma fina e eficiente. Você pode escolher o tamanho certo da tela de acordo com suas necessidades.

Além disso, a máquina trituradora de madeira apresenta alto rendimento, baixo consumo de energia e produz partículas finas e uniformes. Além disso, este equipamento é caracterizado por baixo ruído, mínimo de poeira, ausência de poluição, operação simples, baixos custos de manutenção e facilidade de uso.

Exibição e uso de produtos acabados

As matérias-primas que podem ser processadas por um triturador de madeira são diversas, mas existem requisitos de tamanho padrão. De modo geral, pode esmagar galhos e caules de árvores com diâmetro variando de 70 mm a 250 mm. Os materiais triturados resultantes são partículas com um diâmetro de aproximadamente 3-5 mm.

A máquina trituradora de madeira é projetada para várias tarefas de trituração e reciclagem de madeira, incluindo madeira dura, madeira macia, madeira aglomerada, contraplacado e materiais residuais como sofás e armários de madeira.

Além disso, ele pode lidar com lascas de bambu, palha, talos de milho, talos de sorgo e outros materiais fibrosos. Também é adequado para a produção de matérias-primas para painéis de partículas, painéis de serragem e painéis de alta densidade.

Princípio de funcionamento do triturador de madeira industrial

A madeira é introduzida pela entrada. À medida que as lâminas cortam e esmagam o material, o rotor cria um fluxo de ar de alta velocidade que se move na mesma direção das lâminas. Este fluxo de ar acelera o material, fazendo com que ele seja repetidamente impactado e esmagado de forma mais completa.

Simultaneamente, este processo aumenta a taxa de britagem do material. Em última análise, as aparas de madeira resultantes são expelidas pelo fluxo de vapor de alta velocidade produzido pela lâmina eólica na placa da faca trituradora.

Parâmetros técnicos do triturador de madeira

| Modelo | Capacidade | Tamanho da saída | Poder |

| SL-420 | 600-800KG/H | 0,3-0,8cm | 7,5-11 kW |

| SL-500 | 1000-1500kg/h | 0,3-0,8cm | 18,5 kW |

| SL-600 | 1500-2000kg/h | 0,3-0,8cm | 30 kW |

| SL-700 | 2000-2500kg/h | 0,3-0,8cm | 37 kW |

| SL-900 | 2500-3000kg/h | 0,3-0,8cm | 55 kW |

| SL-1000 | 3000-4000kg/h | 0,3-0,8cm | 75+7,5 kW |

Diferentes modos de energia estão disponíveis

A máquina para fazer serragem de madeira pode ser movida por motores elétricos, motores a diesel ou grupos geradores a diesel. Você pode selecionar a opção que melhor se adapta às suas condições de trabalho locais. Oferecemos personalização e recomendaremos a solução de energia mais adequada com base em suas necessidades específicas.

Máquina trituradora de madeira tipo móvel

Podemos fixar rodas na parte inferior da máquina para facilitar a movimentação dos usuários para diferentes locais.

Triturador de madeira industrial enviado para Maurício

Este cliente tem experiência na importação e já adquiriu duas máquinas de processamento de madeira da China. Agora, ele está procurando outra máquina trituradora de madeira para produzir lascas de madeira para nidificação de frangos. Com base no tamanho e na produção das toras que ele manuseia, recomendamos o triturador de madeira SL-1000.

O cliente ficou satisfeito com a máquina depois de usá-la por um tempo. Conseqüentemente, ele decidiu encomendar um para lançar seu negócio de criação de ninhos de galinha a partir de lascas de madeira. Aqui está uma foto da embalagem e entrega do triturador de madeira industrial. Se você estiver interessado em máquinas de processamento de madeira, sinta-se à vontade para explorar este site e entrar em contato conosco.