Biomass Pellet Machine Flat Die Wood Pellet Mill Inauzwa

| Mfano | 300 |

| Nguvu (KW) | 22+0.37 |

| Pato (kg/h) | 150-300 |

| Mfano | 400 |

| Nguvu (KW) | 37+0.37 |

| Pato (kg/h) | 200-500 |

| Mfano | 450 |

| Nguvu (KW) | 55+0.37 |

| Pato (kg/h) | 300-700 |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Mashine yetu ya gorofa ya biomass pellet ina uwezo wa kutengeneza pellets za mbao kutoka kwa nyenzo mbalimbali kama vile vumbi la mbao, karatasi iliyosindikwa, nyasi, majani na aina nyinginezo za majani. Inatumika kwa kawaida katika nyumba, mashamba madogo, na warsha.

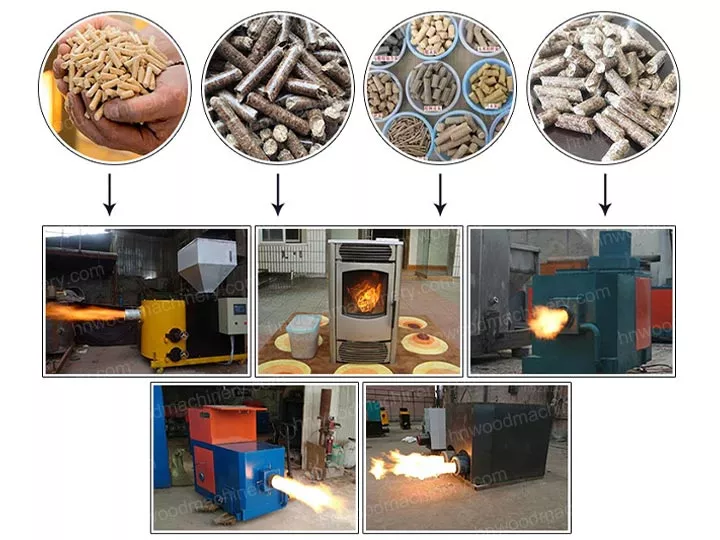

Pellet zilizoundwa zinaweza kufikia urefu wa hadi 3cm na zinafaa kwa matumizi kama vile kupasha joto nyumbani, kupikia, na matandiko ya wanyama. Tunatoa aina mbalimbali za mashine za kuchagua, zenye uwezo wa uzalishaji wa hadi 700kg/h.

Kipenyo cha shimo gorofa, ambayo huamua ukubwa wa pellet ya kuni, inaweza kubadilishwa ili kukidhi malighafi yako maalum na mahitaji ya kipekee. Tumepata uwiano bora wa ukandamizaji kwa zaidi ya malighafi 30 tofauti. Ikiwa una aina maalum ya malighafi, jisikie huru kutuma kwetu, na tutakujaribu bila gharama yoyote.

Gurudumu la ukungu na shinikizo la kinu cha pellet hutengenezwa kwa chuma cha aloi kinachostahimili kuvaa, na kuwapa sifa za nguvu, uimara, na maisha marefu ya huduma. Mashine ya pellet ya biomasi ina muundo wa moja kwa moja, utumiaji mpana, na alama ndogo ya miguu, na hufanya kazi kwa kelele ya chini, na kuifanya kuwa kifaa muhimu kwa watengenezaji wengi wa biomasi.

Vifaa vinavyotumika vya kinu cha pellet ya mbao

Mashine ya pellet ya biomass ya kuni inafaa kwa aina mbalimbali za vifaa. Inaweza kuwa sawdust au mazao, kama vile makundi ya mahindi, majani, maganda ya karanga, makonde ya mahindi, makundi ya pamba, magugu, n.k. Unaweza kutumia mashine ya kusaga kupata vifaa vya sawdust. (Soma Zaidi: Mashine ya Kusaga Kuni kwa Ajili ya Kutengeneza Sawdust>>)

Nishati ya pellet ya biomasi ina thamani kubwa ya joto, kuanzia takriban kalori 3900 hadi 4800 kwa kilogramu. Wakati wa mwako, utoaji wa vipengele vya gesi hatari ni mdogo, na kusababisha utoaji mdogo wa gesi hatari na kutoa faida za kimazingira. Zaidi ya hayo, majivu yanayozalishwa baada ya kuungua yanaweza kutumika kama mbolea ya potashi, ikitoa akiba ya gharama.

Kanuni ya kazi ya mashine ya pellet ya majani

Mashine ya extruder ya pellet ya kuni hufanya kazi kwa kutumia motor (au injini ya dizeli) inayoendesha gia, kuhamisha nguvu kwenye shimoni kuu. Kama matokeo ya nguvu ya msuguano, roller ya shinikizo inazunguka, ikitoa joto la msuguano kati ya roller ya shinikizo na kufa, ambayo husaidia kuweka plastiki nyenzo za unga.

Kisha nyenzo hiyo inasukumwa kupitia shimo la kufa na roller ya kubana. Hatimaye, trei ya kurusha husafirisha mbao zilizokamilishwa kutoka kwa mashine ya majani kupitia lango la kutokeza.

Pellets za kuni zilizokamilishwa zinapatikana kwa kuuza

Mkusanyiko wa malighafi → ukaushaji wa malighafi → chembechembe na ukingo → kuweka mifuko na mauzo.

Vidokezo:

- Kwa kuwa machujo ya mbao hayana haja ya kusagwa, kiungo cha kusagwa kinaachwa, na kinaweza kuwa granulated moja kwa moja baada ya kukausha.

- Kiwango cha unyevu baada ya kukausha kinapaswa kuwa 15-18%. Ikiwa unyevu ni mkubwa sana au mdogo sana, haifai kwa uundaji wa chembe.

Vipengele vya mashine ya kutengeneza pellet ya mbao

- Nyenzo ni kavu na hukauka bila kupoteza unyevu. Inaangazia gia tofauti, upitishaji wa pamoja wa wote, matumizi ya chini ya nishati, na pato la juu.

- Mashine hii ya kutengenezea pellet ya mbao hutumia teknolojia ya hali ya juu kwa granulation extrusion na polishing, kushughulikia ipasavyo changamoto za chembechembe zinazopatikana katika mbinu za kitamaduni.

- Chembe za vumbi la mbao zinazotokana ni sare, laini, na pande zote, zinaonyesha nguvu ya juu na umajimaji bora.

- Roli na ukungu, ambazo mara nyingi hujulikana kama sahani au diski, zimeundwa kutoka kwa aloi sugu ya hali ya juu ambayo hupitia matibabu maalum ya joto ili kufikia ugumu wa hali ya juu na uimara wa muda mrefu.

- Gia za upokezaji zimeundwa kutoka kwa aloi ya ubora wa juu, inayotoa manufaa kama vile uendeshaji laini, viwango vya chini vya kelele, uwezo wa juu wa kupakia, ongezeko kidogo la joto na upinzani bora wa shinikizo.

- Mashine hii ya pellet ya majani ina anuwai ya matumizi. Inaweza kuajiriwa kwa uchenjuaji upya wa taka za kikaboni katika mitambo ya nishati ya mimea, mitambo ya kuzalisha umeme, ufugaji, viwanda vya kulisha, na viwanda vingine mbalimbali.

Vigezo vya mashine ya pellet ya kuni

| Mfano | 300 | 400 | 450 |

| Nguvu (KW) | 22+0.37 | 37+0.37 | 55+0.37 |

| Pato (kg/h) | 150-300 | 200-500 | 300-700 |

Mbali na mashine hii ya pellet ya biomass ya flat die, pia tunazalisha mashine za pellet za biomass za ring die. (Post Iliyohusiana: Mashine ya Kutengeneza Pellet ya Kuni丨Mizani ya Pellet ya Kuni Inauzwa>>)

Jinsi ya kuanza biashara ya kutengeneza pellet ya majani?

Kama mafuta yanayoweza kurejeshwa ambayo ni rafiki kwa mazingira, pellets za biomass hutumiwa hasa kuchukua nafasi ya makaa ya mawe, gesi asilia, n.k., na biashara yao ya uzalishaji inavutia wawekezaji zaidi na zaidi. Kwa hivyo, unapaswa kuzingatia nini ikiwa unapanga pia kutekeleza mradi huu?

- Madhumuni ya pellets unayotaka kuunda ni nini?

- Je, unalenga kuzalisha pellets ngapi?

- Je, unapanga kutumia malighafi gani?

- Je, una bajeti gani kwa mradi huu?

Kiwanda chetu kimebobea katika utengenezaji wa usindikaji wa kuni na mashine za kuchakata tena kwa miaka mingi. Ikiwa unajishughulisha na biashara hii, basi sisi ni chaguo lako bora. Tafadhali vinjari tovuti hii, himiza kila mtu kushauriana wakati wowote, na karibu kutembelea kiwanda chetu. Tunatazamia kushirikiana nawe.