Kayu Hammer Mill Industri Log Kayu Hammermill Crusher

| Model | SL-80 |

| Kekuatan (kw) | 37 |

| Palu (pcs) | 50 |

| Kipas angin (kw) | 7.5 |

| Penghilang debu (pcs) | 5 |

| Diameter siklon (m) | 1 |

| Kapasitas (t/jam) | 1.5-2 |

Anda sekarang dapat bertanya kepada manajer proyek kami untuk rincian teknis

Penghancur pabrik palu kayu dikenal karena memberikan rasio penghancuran yang lebih tinggi pada beragam bahan di sektor industri, mencapai hasil maksimum 5 ton per jam. Ini menghasilkan material yang lebih halus dari 3/16 inci (4 mm). Desainnya yang kokoh dan tahan lama memungkinkan penerapan kekuatan yang lebih besar, sehingga menghasilkan peningkatan produktivitas sekaligus mengelola ukuran dan kualitas maksimum produk akhir.

Hammer crusher ini memiliki efisiensi tinggi, struktur sederhana, kerja stabil, konsumsi energi rendah, dan biaya pemrosesan rendah. Dapat juga digunakan untuk memotong jerami, sedotan, karton, arang, dan bahan lainnya. Biasanya, pabrik palu kayu biasanya digunakan di jalur produksi untuk menghancurkan material lebih lanjut setelah diproses dengan drum chipper atau penghancur terintegrasi.

Mesin pabrik palu kayu yang dapat disesuaikan

Ada beberapa model pabrik palu kayu yang dirancang untuk berbagai tingkat keluaran. Semua penghancur serpihan palu dilengkapi dengan siklon, yang secara efektif mengumpulkan debu dan serpihan yang dihasilkan selama pengoperasian. Fitur ini juga membantu meminimalkan polusi debu di area produksi.

Mesin-mesin tersebut biasanya ditenagai oleh motor listrik atau mesin diesel, sehingga memastikan mesin-mesin tersebut dapat memenuhi beragam kebutuhan daya pelanggan.

Penting untuk dicatat bahwa pabrik palu kayu berbeda dari penggiling kayu, baik dalam jenis bahan yang diproses maupun struktur internalnya. Selain itu, peralatan ini beroperasi dengan tingkat kebisingan yang rendah, mudah digunakan, dan memerlukan perawatan minimal.

Fitur dan manfaat mesin

- Desain bukaan besar, mudah beradaptasi, dan serbaguna.

- Berbagai konfigurasi rotor mengakomodasi material apa pun.

- Layar memungkinkan ukuran produk tepat dan mudah diganti.

- Rumah pengunci positif menawarkan keamanan tambahan terhadap ledakan dan debu.

- Lapisan baja tahan aus dan pelat penghancur mangan cor memastikan masa pakai yang lama.

- Baja paduan yang ditempa dan poros tugas berat ekstra meminimalkan getaran dan memperpanjang umur bantalan.

Berbagai aplikasi penggiling palu kayu

Tanaman yang Berlaku

Rangkaian peralatan ini dirancang untuk penggunaan seluler. Ini umumnya digunakan di area persiapan perusahaan manufaktur papan partikel dan papan serat berukuran kecil hingga menengah. Selain itu, dapat dimanfaatkan oleh rumah tangga perorangan untuk memproduksi serpihan kayu komersial.

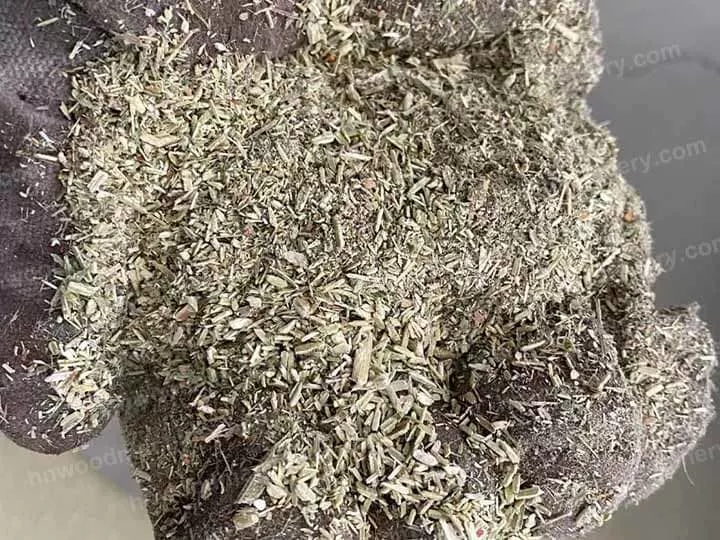

Bahan Baku dan Produk Jadi yang Berlaku

Penghancur serpihan palu utamanya dirancang untuk memproses berbagai jenis kayu, termasuk pinus, kayu campur, kayu poplar, kayu cemara, dan bambu mentah. Mesin ini sangat cocok untuk pemrosesan serpihan kayu di fasilitas budidaya jamur pangan. Selain itu, penghancur dapat digunakan untuk memproduksi bahan baku untuk papan partikel, papan serbuk gergaji, dan papan densitas tinggi.

Prinsip kerja penghancur kayu hammer mill

Penghancur kayu hammer mill terutama menggunakan benturan untuk memecah material. Saat material memasuki mesin, material tersebut dihancurkan oleh kekuatan kepala palu yang berputar berkecepatan tinggi. Selain itu, material yang hancur saling bertabrakan.

Melalui proses penghancuran yang berulang-ulang ini, material menjadi lebih kecil dari lubang saringan dan dibuang melalui celah tersebut. Potongan yang lebih besar ditumbuk lagi hingga masuk ke dalam jaring kasa. Pada akhirnya, produk ukuran partikel yang diinginkan tercapai.

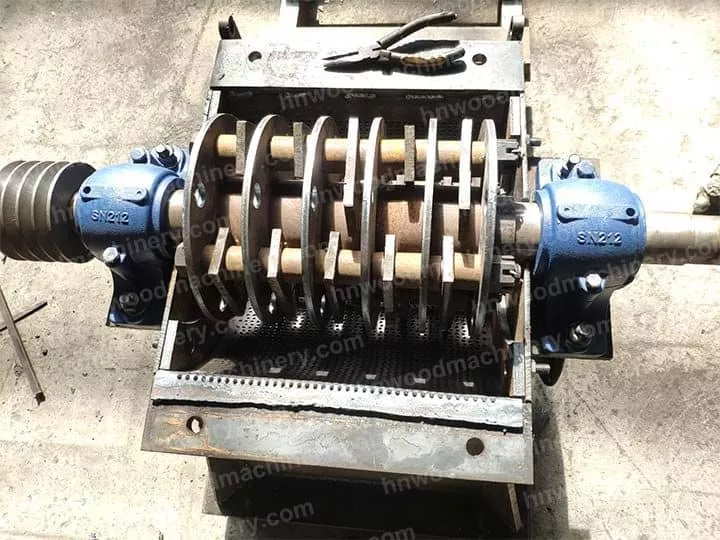

Struktur penghancur kayu palu

Penghancur kayu palu terutama mencakup rangka, rumah, meja bantalan, meja pisau tetap, layar, dan bingkai layar. Seluruh alat berat memiliki desain yang kompak, area pembuangan bubuk yang diperluas, kemampuan penghancuran yang efektif, dan memudahkan penggantian saringan.

Parameter teknis penghancur pabrik palu

| Model | SL-60 | SL-70 | SL-80 | SL-90 | SL-1000 | SL-1300 |

| Kekuatan (kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Palu (pcs) | 30 | 40 | 50 | 50 | 105 | 105 |

| Kipas angin (kw) | 7.5 | 7.5 | 11 | 22 | ||

| Penghilang debu (pcs) | 5 | 5 | 5 | 5 | 14 | 14 |

| Diameter siklon (m) | 1 | 1 | 1 | 1 | 1 | 1 |

| Kapasitas (t/jam) | 0.8-1 | 1-1.5 | 1.5-2 | 2-3 | 3-4 | 4-5 |

Perbedaan antara hammer mill dan penghancur kayu

- Tampilan kedua mesin ini sedikit berbeda. Penghancur serpihan palu memiliki sekrup yang menonjol di atas cangkang bagian mesin penghancur, sedangkan seluruh cangkang penghancur kayu halus.

- Layar mesinnya berbeda. Layar hammer mill berbentuk setengah cincin. Layar penghancur kayu berbentuk lingkaran penuh.

- Bahannya berbeda. Material yang ditangani oleh hammer mill adalah kayu olahan kasar, batok kelapa, jerami, karton, dll. Wood crusher umumnya menangani segala jenis kayu, papan, furniture bekas, dll.

- Struktur internal mesin berbeda. Penghancur bilah palu internal terutama bilah palu, internal penghancur kayu terutama pelat pisau, bilah, dan bilah palu.

Untuk mempelajari lebih lanjut tentang penghancur kayu, silakan klik Mesin Penghancur Kayu untuk Pembuatan Serbuk Gergaji.

Kasus yang berhasil

Pelanggan kami berbasis di Kolombia dan menghubungi kami setelah menonton video YouTube kami. Selama diskusi kami, kami menemukan bahwa pabrik mereka berspesialisasi dalam mengubah berbagai jenis kayu. Saat ini mereka membutuhkan mesin penghancur untuk mengolah berbagai bahan limbah kayu.

Setelah menilai kebutuhan keluaran pelanggan, manajer penjualan kami menyarankan hammer mill model SL-WC700. Pelanggan senang dengan rekomendasi tersebut dan akhirnya memutuskan untuk memesannya.

Kami memahami bahwa kebutuhan setiap klien adalah unik dan menawarkan layanan yang disesuaikan satu per satu. Apakah Anda memiliki pertanyaan? Jangan ragu untuk meninggalkan pesan pada formulir di sebelah kanan dan kami akan segera merespons.