Mesin Pembuat Blok Pallet Peralatan Pembentuk Blok Serbuk Gergaji Kayu

| Ukuran | 90*90mm (Dapat Disesuaikan) |

| Motor | 15-18kw |

| Kapasitas | 4 m³/24 jam (berbeda untuk bahan berbeda) |

| Kepadatan | 550-600kg/m³ |

| Konsumsi bahan | 550-600kg/m³(serutan kayu, serbuk gergaji) |

| Konsumsi lem | 80-100kg/m³ |

| Kontrol suhu | PID |

| Dimensi | 4800*760*1300mm |

| Berat | 1300Kg |

Anda sekarang dapat bertanya kepada manajer proyek kami untuk rincian teknis

Mesin pembuat blok palet khusus memproduksi alas anyaman baki seret dan blok anyaman lapisan pelindung, yang digunakan untuk transportasi dan penyimpanan. Ini dapat memproses sekitar 4m³ bahan mentah per hari. Kepadatan produk akhir bisa mencapai 550-1000kg/m³.

Kami dapat menyesuaikan bentuk dan ukuran balok kayu jadi, mulai dari 75 mm hingga 145 mm. Mesin pembuat balok palet kami dapat menghasilkan dua jenis balok kayu, padat dan berongga. Anda dapat memilih sesuai dengan kebutuhan Anda.

Mesin pembuat blok palet Shuliy dapat menghasilkan balok kayu berkualitas tinggi dengan menggunakan bahan baku serbuk gergaji kayu. Produk jadi tidak memiliki sisa yang lepas dan menunjukkan ketahanan air yang baik. Mesin ini telah diterima dengan baik oleh banyak pelanggan.

Selain itu, kami menawarkan dua jenis mesin pembuat balok serbuk gergaji: satu adalah model umum dan yang lainnya adalah model standar Eropa. Mesin standar Eropa sedikit lebih mahal. Namun terdapat perbedaan antara kedua mesin tersebut. Jika anda berminat, silahkan menghubungi kami untuk informasi lebih lanjut.

Bahan baku yang digunakan pada mesin pembuat balok serbuk gergaji

Bahan baku yang digunakan dalam mesin pembuatan blok serbuk kayu umumnya adalah serbuk kayu, chip kayu, serutan kayu, dll., mirip dengan bahan baku yang digunakan dalam mesin pembuatan palet kayu tekan.

Dua jenis balok kayu

Ada dua jenis balok kayu yang kami produksi: solid dan hollow. Namun kami merekomendasikan balok berlubang karena dapat menyerap keringat, sehingga panas dapat hilang dan mencegah penumpukan kelembapan.

Ukuran balok kayu serbuk gergaji

Ukuran umum: 80*80mm, 90*90mm, 100*100mm.

Ukuran standar Eropa: umumnya di atas 100mm, misalnya, 145*105mm.

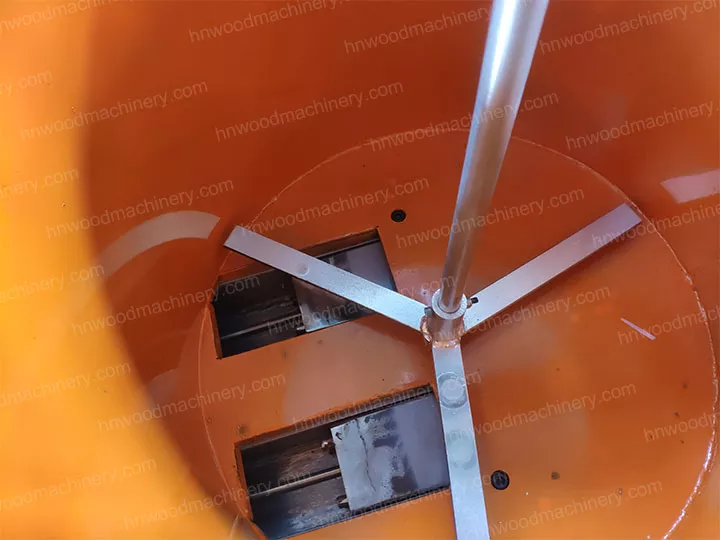

Struktur mesin press panas blok kayu serbuk gergaji

Mesin pembuat blok palet berisi kabinet kontrol listrik, hopper, alat pendorong hidrolik, alat pemanas dan pembentuk, saluran keluar (dengan saluran keluar ganda dan saluran keluar tiga), gergaji (manual atau otomatis), dll.

Parameter mesin pembentuk blok serbuk gergaji

| Ukuran | 90*90mm (Dapat Disesuaikan) |

| Motor | 15-18kw |

| Kapasitas | 4 m³/24 jam (berbeda untuk bahan berbeda) |

| Kepadatan | 550-600kg/m³ |

| Konsumsi bahan | 550-600kg/m³(serutan kayu, serbuk gergaji) |

| Konsumsi lem | 80-100kg/m³ |

| Kontrol suhu | PID |

| Dimensi | 4800*760*1300mm |

| Berat | 1300Kg |

Prinsip kerja mesin blok palet

- Silinder hidrolik menghasilkan tekanan tinggi, menggerakkan piston untuk mengekstrusi dan membentuk material.

- Pelat pemanas, yang disetel ke suhu tinggi, membantu pemadatan dan pencetakan lem urea-formaldehida.

- Bahan tersebut kemudian dipotong dengan panjang tertentu, biasanya sekitar 1,2 meter.

- Setelah pendinginan, potongan kayu panjang dari produk setengah jadi dipotong hingga ukuran akhirnya.

Mesin bekerja sama dengan pembuat blok serbuk gergaji

Mesin pembuat balok serbuk gergaji dapat dikombinasikan dengan penghancur, pengering aliran udara (dengan tungku), pengaduk perekatan, pemotong balok kayu, dll. untuk membentuk jalur produksi. Kami dapat mencocokkan lini produksi mesin balok kayu sesuai dengan situasi aktual pelanggan.

Manfaat mesin pembuat blok serbuk gergaji

- Ada berbagai jenis serbuk gergaji mesin pembuat blok, yang dapat memenuhi kebutuhan pelanggan yang berbeda.

- Efek kerja yang baik, briket yang dihasilkan indah, bersih, dan tahan lama.

- Mesin pembuat blok palet tahan lama dan memiliki masa pakai yang lama.

- Mudah digunakan, dengan kabinet kontrol listrik, dan mudah dioperasikan.

- Mudah dioperasikan, satu orang dapat mengoperasikan 3 mesin.

- Mesin ini dapat mendaur ulang limbah kayu secara efektif.

Apa kelebihan balok kayu serbuk gergaji?

- Karena balok kayu dibentuk melalui ekstrusi suhu tinggi, maka bebas dari fumigasi.

- Biaya produksi rendah. Balok tikar kayu terdiri dari serpihan kayu, bahan bakunya murah dan mudah didapat.

- Kinerja menahan beban yang tinggi. Ini dapat mendukung sebagian besar item dan digunakan secara luas.

Pabrik kami telah memproduksi peralatan pengolahan kayu selama bertahun-tahun dan memiliki pengalaman yang kaya. Jika Anda terlibat dalam industri ini, Anda mungkin ingin menjelajahi situs web ini dan jangan ragu untuk menghubungi kami. Kami akan menjadi pilihan terbaik Anda.