动物床上用品刨花价格优惠木材刨花机

| 模型 | SL-1000 |

| 容量 | 1500公斤/小时 |

| 输入尺寸 | 20厘米 |

| 力量 | 55千瓦 |

| 模型 | SL-1200 |

| 容量 | 2000公斤/小时 |

| 输入尺寸 | 24厘米 |

| 力量 | 55千瓦 |

您现在可以向我们的项目经理询问技术细节

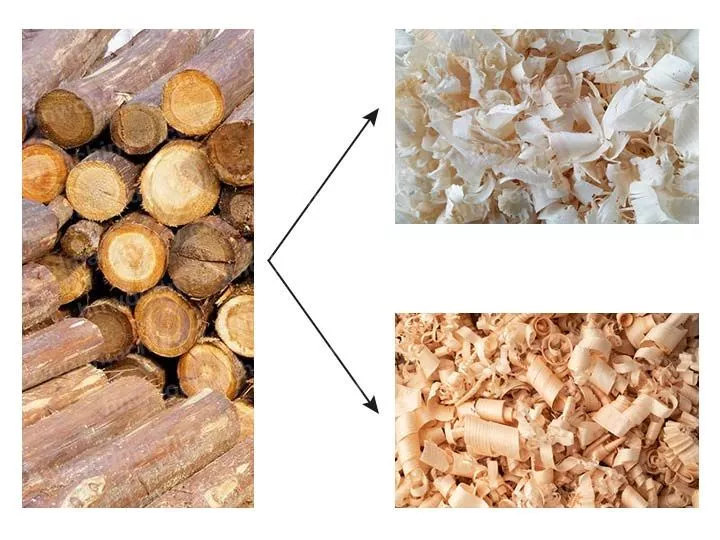

刨花机专门用于将不同直径的圆木刨花成动物垫料的优质刨花。它通过旋转刀片来产生超细切屑,精度高达 0.5 毫米。

它每小时可处理多达 3,000 公斤原木,这有助于将生产过程中的能耗降低 20%。无论是用于家具制造、板材生产,还是建筑材料的预处理,都有助于提高生产效率。

成品刨花大小可调,可作为马、猪、牛、羊、鸡、宠物等牲畜饲养和繁殖的垫料,对养马业、畜牧业或畜牧业非常有利。

用于动物垫料的可定制机器刨花

Shuliy 的木材刨花机有不同的型号。我们可以满足更多客户的需求。我们还可以根据客户的具体需求定制机器。

例如,我们可以将动物垫料刨花的框架抬高,增加两个大轮,以方便客户移动机器等。可以根据需要调整刀的深度,以获得不同厚度的刨花。

动力方面,该机可配备柴油机和电动机。我们经常出口的国家是南非及周边地区。

在刨花加工前,您可以使用我们的原木去皮机对原木进行预处理。

木材刨花机的应用范围

原材料:原木(去皮后效果更佳)、树枝等。

成品应用

- 可制成刨花板(胶合板),造纸厂用作木浆纸的原料,运输公司用作易碎物品运输的填充物。

- 也可用作小型猪、牛、羊及各种动物巢穴的填充物和生物能源。

- 本机适用于中小型企业,以及个体木材加工户如刨花板厂、制板厂、造纸厂、生物能源燃料、宠物垫料、家禽饲养垫料窝、物流易碎品等使用寝具。

- 也用于蘑菇种植和种植基地。

工业木材刨花机技术信息

| 模型 | 容量 | 输入尺寸 | 力量 |

| SL-420 | 300公斤/小时 | 6厘米 | 7.5千瓦 |

| SL-600 | 500公斤/小时 | 12厘米 | 15千瓦 |

| SL-800 | 1000公斤/小时 | 16厘米 | 30千瓦 |

| SL-1000 | 1500公斤/小时 | 20厘米 | 55千瓦 |

| SL-1200 | 2000公斤/小时 | 24厘米 | 55千瓦 |

| SL-1500 | 2500公斤/小时 | 32厘米 | 75千瓦 |

松木刨花机结构

松木刨花机主要包括机架、进料口、刀板、刀片、筛网、出料口等。一般小型刨花机还配有沙克龙,可以集中机器工作时产生的粉尘。 。我们还可以根据客户的要求升高车架和安装轮子。

木材刨花机是如何工作的?

原料进入进料口后,受到高速旋转的锤子的冲击而破碎。然后剪切刀将其切入破碎室。

然后内置风叶产生的风通过筛网送到出料口,或者使用外部风机将风抽到出料口。

通过调节刀片长度和筛网孔径大小来确定刨花的大小,以满足各种需要。

盘式刨花机刀具和刀片

- 刨花系统是机器最重要的部分,它包含刀板和刀片。

- 我们生产的刀盘和刀片均采用优质材料制成,坚固耐用,锋利,并提供良好的剃须效果。

- 另外,刀片数量因型号而异,有四刀片和八刀片可供选择。

- 可以调节刀片的倾斜度来控制刨花的厚度。

商用木材刨花机的亮点

- 商用木材刨花机布局合理,安装方便,操作、维护方便。

- 刀具安全、耐用且噪音低。

- 设计合理,采用高锰钢制造,结构紧凑。

- 仅由一台电机驱动,效率高,性价比高。

- 动物垫料刨花生产速度快,节省大量时间和人力。

- 生产出来的成品刨花薄、柔软、质感好。

- 木材和刀片之间的接触压力保持恒定,木材的往复速度也保持恒定,从而产生厚度均匀的刨花。

成功案例

客户来自阿布哈兹,是一家木材厂的采购经理。他在观看我们的YouTube视频后联系了我们。通过沟通,客户表达了对更大尺寸刨花的需求,用于动物垫料。

我们的销售经理向客户提供了大型刨花机的图片、视频和参数。最终客户选择了产能为1000KG/H的SL-800机型。之后我们及时提供了机器的PI。客户看到后很满意并下单了剃须刀。

我们的服务

我们提供一套备件和包装。所有机器在发货前均经过测试。此外,机器采用标准出口木箱包装,我们长期合作的运输公司将准时、安全地发货。

对于售后服务,我们提供一年保修期,您可以从我们这里购买备件。同时,我们可以提供专业的咨询和问题解决方案。