Maschine zur Herstellung von Holzpellets, Ringmatrizen-Pelletmühle zu verkaufen

| Modell | YGKJ700 |

| Kapazität | 2–2,5 t/h |

| Leistung | 160+2,2+ 0,37+0,75 +1,5KW |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

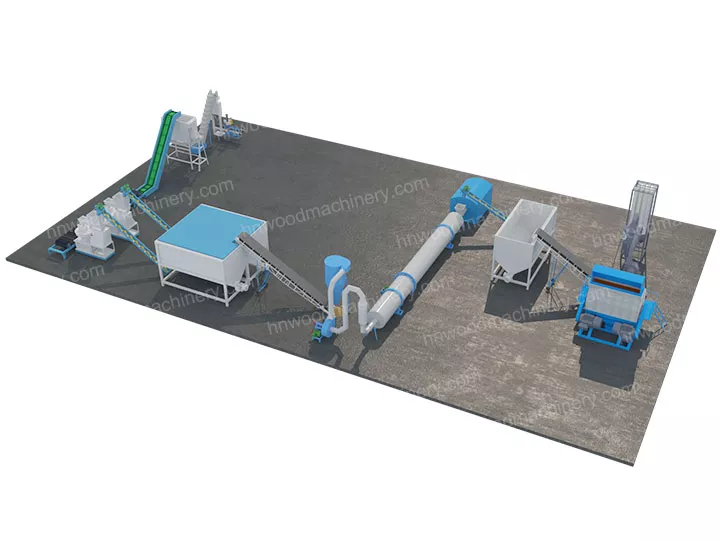

Die Maschine zur Herstellung von Holzpellets ist ein Gerät, das verschiedene Arten von zerkleinertem Holz, Pflanzenstroh, Pflanzenschalen und Schlacke in Biokraftstoffpellets umwandelt. Die Ringmatrizen-Pelletmühle kann bis zu 4000 kg/h produzieren und wird häufig für die Produktion in großem Maßstab eingesetzt. Die erzeugten erneuerbaren Brennstoffpellets sind glatt und dicht, was sie für viele Benutzer zur ersten Wahl macht.

Shuliy bietet eine Vielzahl von Maschinen zur Herstellung von Holzpellets mit jeweils unterschiedlichen Leistungskapazitäten an. Kunden können je nach Bedarf aus mehreren Modellen wählen. Neben diesen Maschinen bieten wir auch kleinere Holzpelletmaschinen für diejenigen mit geringeren Leistungsanforderungen an.

Unser Ziel ist es, die am besten geeigneten Maschinen zu empfehlen, die auf die spezifischen Bedürfnisse unserer Kunden zugeschnitten sind. Um den Komfort und die Effizienz zu steigern, liefern wir auch Zuführmaschinen und Förderbänder, die einen reibungslosen und kontinuierlichen Betrieb ermöglichen.

Rohstoffe für die Maschine zur Herstellung von Holzpellets

Die Holzpelletmühle ist in der Lage, eine Vielzahl von Materialien zu verarbeiten, wobei der Schwerpunkt hauptsächlich auf Holzprodukten wie Holzspänen, Sägemehl, Ästen und Baumstämmen liegt.

Darüber hinaus können auch andere Rohstoffe wie Palmfasern, Bagasse, Erdnussschalen, Maisstängel, Weizenstroh und zahlreiche landwirtschaftliche Abfälle verarbeitet werden. Diese Materialien sind leicht verfügbar, kostengünstig und können für verschiedene Anwendungen in Biomassepellets umgewandelt werden.

Verwendung der fertigen Holzpellets

Biomassepellets werden hauptsächlich in Biomassekraftwerken, Biomassekesseln, zum Heizen von Häusern und in verschiedenen industriellen Anwendungen eingesetzt. Daher bieten Investitionen in den Biomassebrennstoffsektor zur Errichtung von Pelletproduktionsanlagen ein erhebliches Marktpotenzial.

Struktur der Pelletiermaschine für Holzbiomasse

Die Maschine zur Herstellung von Holzpellets besteht aus mehreren Schlüsselkomponenten, darunter Zufuhröffnung, Zufuhrzylinder, Beobachtungsfenster, Abdeckplatte, Motor, Staubschutz, Auslassöffnung, Getriebe und mehr. Sein Gesamtdesign ist effizient, benötigt nur minimale Stellfläche und ist gleichzeitig robust, langlebig und verschleißfest.

Wie funktioniert der Holzpellet-Extruder?

Über eine Förderschnecke wird das Rohmaterial in die Pelletmühle eingebracht und von dort in den Konditionierer geleitet. In dieser Phase wird ein Haftmittel hinzugefügt, um die Partikel miteinander zu verbinden und so die Bildung dichter und fester Pellets zu erleichtern.

Nach der Konditionierung gelangt das Rohmaterial in den Pelletierbereich. Dieser Abschnitt verfügt über eine ringförmige Matrize, weshalb diese Anlage zur Herstellung von Biomassepellets als Ringmatrizen-Pelletmühle bezeichnet wird. Im Inneren der Ringmatrize befinden sich zwei bis vier Walzen. Wenn das Rohmaterial in diese Kammer gelangt, wird es durch die Zentrifugalkraft gegen die Innenfläche der Ringmatrize gedrückt. Typischerweise drehen sich sowohl die Walze als auch die Ringmatrize und verdichten das Rohmaterial zwischen ihren Oberflächen.

Das komprimierte Rohmaterial extrudiert durch die Löcher der Ringdüse und tritt in Form von Stäbchen aus. Ein messerähnlicher Hobel schneidet diese Stäbchen dann, um Pellets in der gewünschten Größe zu produzieren, sodass die Pelletlänge entsprechend den spezifischen Anforderungen angepasst werden kann.

Parameter des Holzpelletherstellers

| Modell | YGKJ380 | YGKJ450 | YGKJ560A | YGKJ560B | YGKJ560C | YGKJ700 | YGKJ880 |

| Kapazität (T/H) | 0.2-0.3 | 0.6-0.8 | 1-1.3 | 1.2-1.5 | 1.2-1.5 | 2-2.5 | 3-4 |

| Leistung (KW) | 22+0.75 | 55+1.5+ 1.1+0.37+ 0.55 | 90+1.5+ 1.5+0.55+ 0.37 | 90+1.5+ 1.5+0.55+ 0.37 | 90+1.5+ 1.5+0.55+ 0.37 | 160+2.2+ 0.37+0.75 +1.5 | 220+3+0.5 5+2.2+1.1 |

Warum ist die Ringmatrizen-Pelletmühle bei Investoren beliebt?

- Unsere Maschine zur Herstellung von Holzpellets zeichnet sich durch ein unkompliziertes Design aus, ist äußerst anpassungsfähig, nimmt wenig Platz ein und arbeitet mit minimalem Lärm.

- Traditionelle Energiequellen haben Schwierigkeiten, mit den Anforderungen des Weltmarktes Schritt zu halten, sodass Biomasse-Pelletbrennstoff eine praktikable Alternative zu Kohle darstellt.

- Pulverförmiges Futter und Graspulver können ohne Zugabe von Flüssigkeit granuliert werden. Dadurch bleibt der Feuchtigkeitsgehalt des Pelletfutters sehr niedrig, was die Lagerung erleichtert.

- Zu den Rohstoffen für eine Ringdüsen-Pelletmaschine zählen vor allem Erntestroh und ähnliche Materialien. Diese Inputs sind kostengünstig, was zu niedrigen Kosten pro Tonne führt. Darüber hinaus zeichnet sich die Maschine durch eine hohe Verarbeitungsleistung aus. Angesichts der großen Marktnachfrage erweist sich diese Branche als recht profitabel.

Unterschiede und Vorschläge zwischen Ringdüsen- und Flachdüsen-Pelletmaschinen

Es gibt zwei allgemeine Arten von Biomasse-Pelletpressen. Neben dieser Maschine wird die andere Art als Flachdüse-Pelletpresse bezeichnet. Beide haben unterschiedliche Designs, Arbeitsprinzipien, Produktionskapazitäten usw. Aber sie haben die gleiche Funktion – die Produktion von Biomasse-Pellets.

- Die Leistung einer Flachmatrizen-Pelletmaschine liegt typischerweise zwischen 1,5 und 3 kg, während Pelletherstellungsmaschinen 0,2 bis 0,3 Tonnen produzieren können. Wenn Sie also eine höhere Leistung anstreben, ist es ratsam, sich für eine Pelletiermaschine mit Ringmatrize zu entscheiden.

- Es sind verschiedene Fütterungsmethoden zu berücksichtigen. Bei einer Flachmatrizen-Pelletmaschine gelangt das Material aufgrund seines Gewichts vertikal in die Presskammer. Im Gegensatz dazu verwendet die Maschine zur Herstellung von Holzpellets einen gebogenen Futtertrog, der das Futter rollt und komprimiert.

- Wenn es um Partikelfinish und Kompressionsverhältnis geht, bietet der Ringdüsengranulator im Vergleich zur Flachdüsen-Pelletmaschine einen größeren Einstellbereich. Die mit der Ringmatrizenmaschine hergestellten Pellets weisen tendenziell eine glattere Oberfläche auf als die mit der Flachmatrizenmaschine hergestellten Pellets. Wenn Sie spezielle Anforderungen an das Kompressionsverhältnis und das Aussehen der granulierten Produkte haben und gleichzeitig eine höhere Leistung benötigen, ist eine Maschine zur Herstellung von Holzpellets die bessere Wahl.

Warum sollten Sie sich für die Holzpelletmühle von Shuliy Machinery entscheiden?

Unsere Biomasse-Pelletmaschine ist sehr beliebt. Und viele Biomasse-Pelletfabriken im In- und Ausland haben sich für unsere Maschine entschieden. Jetzt wurden unsere Maschinen nach Uganda, auf die Philippinen, nach Senegal, Malaysia, Mexiko, Australien und in andere Länder verkauft.

- Shuliy ist ein erfahrener Hersteller von Holzmaschinen und bringt jahrelange Expertise in die Branche ein.

- Wir sind auf die Entwicklung und Anpassung einzigartiger Maschinen spezialisiert, die auf die spezifischen Anforderungen unserer vielfältigen Kunden zugeschnitten sind.

- Unser engagiertes Vertriebsservice-Team steht den Kunden sowohl online als auch offline professionell zur Seite.

- Kunden können bequem online bezahlen und ihre Logistik überwachen, um ein sicheres Einkaufserlebnis zu gewährleisten.

- Alle Komponenten unserer Maschinen sind aus hochwertigen, verschleißfesten Materialien gefertigt, die typischerweise in Schwermaschinen verwendet werden.

Nach einer Untersuchung der Kosten und Gewinne, die mit der Biomasse-Pelletverarbeitungsindustrie verbunden sind, wird deutlich, dass das Investitionspotenzial für die Ringdüsen-Pelletmaschine recht groß ist und weiterhin eine gesunde Gewinnspanne besteht. Wenn Sie in die Biomasse-Pellets-Verarbeitungsbranche einsteigen möchten oder eine Ringmatrizen-Pelletmaschine kaufen müssen, können Sie uns jederzeit kontaktieren.