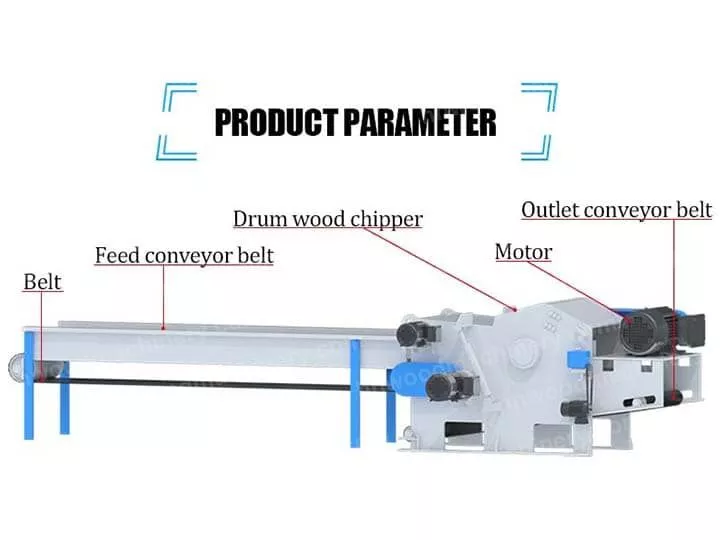

鼓式木材削片机商用木片制造机

| 模型 | SL-218 |

| 刀具数量 | 2 |

| 进料尺寸 | 300*680毫米 |

| 容量 | 10-15吨/小时 |

| 原材料尺寸 | ≤300毫米 |

| 木片尺寸 | 25 毫米(可调节) |

| 主电源 | 110千瓦 |

| 重量 | 8600 公斤 |

| 进料口输送机 | 6米 |

| 出口输送机 | 8米 |

| 包装尺寸 | 3105*2300*1650 毫米 |

您现在可以向我们的项目经理询问技术细节

鼓式木材削片机配备了先进的切割系统。它可以轻松处理各种硬度的原木和树枝,进行精确、快速的削片作业,加工能力可达每小时 15 吨木材。

由于该机产量高,一般用于大中型木材加工企业。木片一般用于木材破碎、造纸、燃料、制作各种板材等前的粗碎。

鼓式削片机配备自动送料传送带,可显着减少时间和劳动力需求。此外,鼓式削片机中的压力辊主动将材料推入削片系统。

This machine can be integrated with a conveyor belt and a hammer mill to create a complete production line for processing wood chips. Additionally, we also manufacture smaller small wood chippers.

Raw materials: this drum wood chipper machine is capable of processing various materials such as maidenhood, lumber, logs, and small-diameter wood. (Please note that the materials used with this machine should not contain nails).

Application scope of wood chips: the wood chips produced can be utilized for making paper, manufacturing particle board, and fiberboard, or as fuel. Additionally, we can sell the wood chips directly.

工业木材削片机的独特优势

- 工作能力强。它可以高效地加工各种材料。最终产品加工效果良好。

- 机器使用寿命长:机器的刀辊、刀板、刀片均采用优质材料制成,耐磨、耐用。

- 鼓式木材削片机具有独立的电气控制柜,因此该机使用安全,操作方便。

- 削片机可以自动调节进料口的大小。根据原料厚度的不同,上喂料辊借助液压系统可在一定范围内上下浮动。

滚筒式木材削片机内部结构

鼓式削片机主要包括机体、刀辊、进出料机构、液压系统、给料装置等部分。

- 机身:全部采用高强度钢板焊接而成,是整机的支撑底座。

- 刀辊:刀杆上安装有数把飞刀。并通过压块将飞刀固定在刀辊上。

- 液压系统:油缸由油泵供油,可启动机盖,方便更换刀片。维修时可将上送料辊组件抬起,方便调整飞刀与底刀间隙。

- 上下送料机构:由送料接口、上下送料辊、送料间隙调节机构组成。从进料口进入的木材被上、下进料辊压紧,并以一定的速度送入削片机构。

大型商用木材削片机规格

| 模型 | SL-218 | SL-216 |

| 刀数量 | 2 | 2 |

| 进料尺寸 | 300*680毫米 | 230*500毫米 |

| 容量 | 10-15吨/小时 | 5-8吨/小时 |

| 原材料尺寸 | ≤300毫米 | ≤230毫米 |

| 木片尺寸 | 25 毫米(可调节) | 25毫米(可调) |

| 主电源 | 110千瓦 | 55千瓦 |

| 重量 | 8600 公斤 | 5600公斤 |

| 进料口输送机 | 6米 | 6米 |

| 出口输送机 | 8米 | 8米 |

| 包装尺寸 | 3105*2300*1650 毫米 | 2735*2200*1200毫米 |

这台木片制造机是如何工作的?

木材通过进料口送入,当木材与切割刀片接触时,随着切割刀片的高速旋转而被切割。

切割机构是一个旋转的鼓轮,其上安装有几把飞刀。刀具旋转将木材加工成碎片。

There are several square holes on the outer edge of the drum wheel, and the cut pieces of qualified material fall through the mesh screen holes and are discharged from the bottom. The larger pieces of material will be cut again in the woodchipper machine.

为什么选择 Shuliy 鼓式木材削片机?

- 全新设计的叶片转子,叶片更换方便。

- 破碎室盖可液压打开,方便维护和刀片更换。

- 屏幕尺寸可根据最终产品尺寸的不同要求定制。液压缓冲系统确保运行平稳。

- 反向进给装置,带机可反向前进。该装置可以在遇到大块木材时保护机器。

- 比传统机型容量更大、进给尺寸更大,可切割直径230-500mm的原木。

我厂专业生产、制造木材加工机械多年,积累了丰富的经验和先进的技术。我们真诚地邀请您随时与我们咨询,并热忱欢迎您来我厂参观。我们期待与您的合作。